Discover the fascinating world of types of CNC machines and their impact on industries like aerospace, medical, and furniture production. Learn about milling, lathes, routers, and how CNC technology revolutionizes manufacturing with precision and automation.

Exploring the Different Types of CNC Machines and Their Applications

Have you ever wondered how all sorts of nifty gadgets and gizmos get made? From cell phones to spacecraft, CNC machines play an important role behind the scenes. These computer-controlled tools help turn digital designs into awesome real-life objects. Learning about the different types of CNC machines will blow your mind! join us as we explore how milling machines, lathes, lasers and more transform technology. Get ready to discover the wonder of CNC!

What are CNC Machines?

CNC machines bring change to the manufacturing process by cutting, drilling, shaping, and finishing materials with accuracy and speed. CNC is an acronym that is defined as a Computer Numerical Control and these are highly specialized tools that are used to turn digital designs into real-life parts with extreme precision. Impact of CNC machining makes it possible to pre-program machine tool functions via software in repetitive, predictable cycles. This technological advancement in manufacturing increases productivity and allows for higher precision than manual processes.

What is CNC Machining?

We use CNC machining to control machine tools by computer programming. types of CNC machines operates by the help of numerical control. In this we design a software program to control an object.The language behind CNC machining is alternately referred to as G-code, and it’s written to control the various behaviors of a corresponding machine.

Importance of CNC Machines

We can not deny the importance of CNC machines because they have significantly changed the manufacturing landscape. In industries, we can produce complex shapes by the help of CNC machines with high precision. CNC machines are indispensable in industries where accuracy is crucial.In this section, we are going to discuss the importance of these machines:

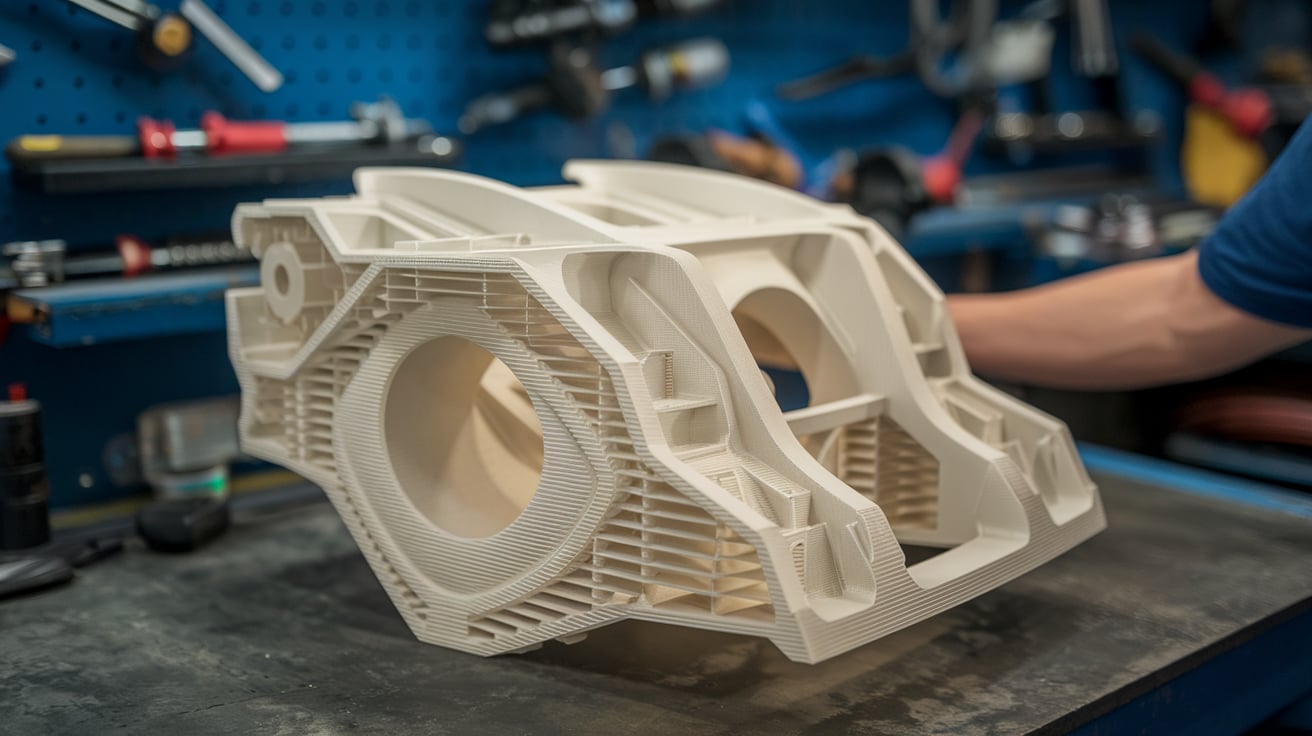

Prototyping and Testing

CNC technology is not limited to manufacturing processes only. It is used in prototyping and 3D modeling. It makes it easier for engineers to design products and make models that look like the final models. These models are, in fact, used to approximate real-world applications and evaluate certain functionalities, which is easily achievable due to the precision of types of CNC machines routers in reproducing parts.

Streamlined Production

The furniture industry also reaps the benefits and reduce CNC machining costs. With these machines, production of both simple and intricate furniture designs is streamlined, translating complex cuts and details into reality while drastically reducing production times.

Defense Applications

As for the defense industry, types of CNC machines is just as critical since it enables creating elements of machines, as well as device parts, with the required accuracy for them to function in the severest conditions possible.

Specifically, the CNC machines have revolutionized the manufacturing industry globally due to their automation of processes with high precision. Despite the fact that each of the machines differs in type and purpose, all represent the highest level of technological advancement for automated production. Here is a closer look at these industrial innovations:

Different Types of CNC Machines

CNC Milling Machines

One versatile tool in any workshop is the CNC milling machine. Employing rotary cutting tools, mills remove material from workpieces, following digital instructions to shape parts accurately according to specifications.Milling machines come in endless variations. More basic models allow three linear movements along the X, Y and Z axes for two-dimensional profiling. Complex advanced designs feature additional rotational axes for true three-dimensional machining.

Whether vertically or horizontally-oriented, common milling attachments include end mills, face mills and helical mills suitable for a vast array of metal cutting tasks. With options for drills, taps and more, mills flexibly produce intricate designs that manual machining could never achieve.

CNC Lathe Machines

For cylindrical components like rods, bushings or shafts, types of CNC machines lathes excel. By rotating workpieces against single-point cutting tools, lathes turn uniform cylindrical stock into symmetrical final parts.Specialized lathes include turret, engine and multi-tasking varieties. Turret lathes position multiple tools on an indexing turret while engine lathes consolidate turning in a single spindle. Advanced lathes incorporate milling or grinding functions, highlighting these tools’ modular design.Regardless of lathe type, a spindle rotates workpieces amid the sliding action of carriages and compound rests. Servo motors precisely coordinate tool motions to produce symmetrical features through grooving, facing and threading operations.

CNC Routers

Ideal for woodworking, signmaking or pattern routing, CNC routers cut intricate designs on flat work surfaces. Equipped with end mills or drill bits, routers replace manual tools like spindle molders or jigsaws, automating artistic visions.

Affordable compact variants facilitate small shop applications while larger gantry style models handle assemblies or architectural elements. Regardless of scale, routers provide a cost-effective entry into types of CNC machines for crafts and education while decreasing material waste.

Types of CNC Machines Based on Axes

The number of controllable axes defines a CNC machine’s operational capabilities. Understanding these distinctions helps match the optimal tool to your needs.

3-Axis Machining

3-axis machines are the workhorse of production, moving tools along the X, Y and Z planes. For basic profiles and holes, nothing beats the simplicity and affordability of 3-axis machining. Its ubiquity makes it well-suited to smaller outfits or training environments.

4-Axis Machining

Building upon the solid foundation of 3-axis control, 4-axis machines boost versatility with rotational ability around the X-axis via the A-axis. This enhanced positioning streamlines multi-sided jobs, reducing setups. Medicine and aerospace leverage such precision for complex parts.

5-Axis Machining

As pinnacle performers, 5-axis CNC machines empower sculpting of any 3D form. Their inclusion of a secondary rotary axis, typically B or C, lets tools access all surfaces simultaneously. Though more costly initially, 5-axis solutions raise precision cnc machining to new heights for intricate molds, gears and other heavily contoured components.

Selecting between configurations relies on balancing design complexity with tolerance needs against budget. While 3-axis covers basic work, solutions like 4-axis and 5-axis CNC machines elevate abilities for advanced applications. The available axes profoundly impact machining scope. Understanding these distinctions guides choice of the right types of CNC machines for specialized tasks.Overall, counting axes offers useful intuition into a tool’s motion souplesse. With functionality scaling up from three to five, CNC machinery caters variably to evolving production demands through high-precision machining.

Applications of CNC Machines

CNC machines have made an indelible impact across diverse sectors by facilitating production with unparalleled precision. Let’s explore several industries reliant on their capabilities:

Aerospace

In this industry, tolerances are tightened to microscopic levels. Types of CNC machines rose to this challenge, earning the trust of aerospace manufacturers. With capabilities like ±0.0001 inch accuracy, these tools produce parts rated for extremes like supersonic flight.

Electronics

The electronics industry demands relentless miniaturization and performance gains. Choose custom CNC machining services create compact, precise components meeting these demands. Their applications include consumer electronics, where precision is paramount. With CNC machining capabilities, electronics continuously evolve.

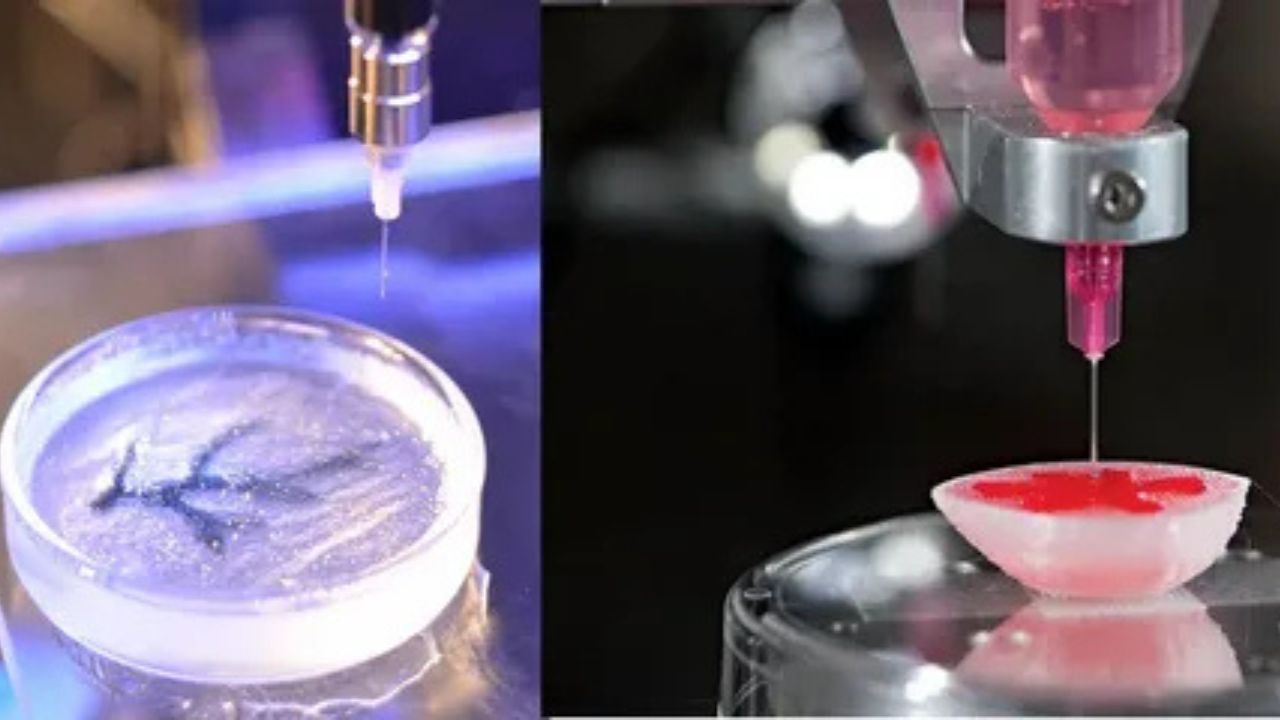

Medical

The medical field necessitates the highest standards of precision. Here, CNC machines assume great responsibility producing parts tailored to individual needs. Their consistency in manufacturing large volumes with precision is essential due to disposable devices’ nature. Precision types of CNC machines machining continually pushes forward life-changing innovations.

Furniture Production

Once a slower, multi-day process, furniture production blossomed with CNC integration. Complex designs translated directly from CAD to precise componentry in minutes. Personalization, small batches, and rapid prototyping are enriched.

Marine Industry

Crafting vessels and specialized underwater equipment demands reliability in corrosive environments. Types of CNC machines delivers components ensuring functionality where failure is not an option. Precision parts protect maritime investments on the open seas.

Oil and Gas

Where components interact under pressure, precision is equally important. CNC machined parts guarantee equipment like drills and pipelines perform as intended. CNC machining’s exactness maintains safety and efficiency within petrochemical industry complex machinery.

Military and Defense

Harsh working conditions lend no room for error in this sector. Types of CNC machines ensures machine components and devices perform as designed when risking lives depends on it. Their stringent quality standards are strictly enforced.

Advantages of CNC Machines in Manufacturing

The integration of CNC machines has empowered manufacturing in remarkable ways. By optimizing production processes, these technological wonders yield substantial returns across operational efficiency, quality control, and broader capabilities. Their inherent strengths justify widespread adoption across sectors.

Precision Without Compromise

Digital automation endows types of CNC machines with repeatable precision that surpasses human ability. Tolerances tightened 100-fold are now commonplace. Through computer-driven toolpaths and feedback loops, these marvels attain an unmatched level of dimensional accuracy with every passing cycle.

Versatility for Vast Materials

Adaptable tooling allows a CNC machine to seamlessly transition between dissimilar materials. Whether processing non-ferrous alloys or engineered composites, these wonders reliably churn precise components devoid of damaging machine-specific variations. Their modularity streamlines transitions between short-run specialty jobs and mass production equally well.

Maximized Throughput

Cutting parameters and feed rates are endlessly optimized according to each toolpath using data analysis. Hours of non-productive manual adjustments are eliminated through digital workflows. As a result, types of CNC machines routinely doubles typical part turnover versus comparable manual systems.

Continuous Improvement

Innovations in areas like Artificial Intelligence and Big Data promise to dynamically self-adjust cutting parameters in real-time. Predictive diagnostics will likely take downtime reductions to an exponential level. The future remains bright as technological synergy unleashes each types of CNC machines full untapped potential.

These benefits justify CNC machining’s widespread rise across sectors. For aerospace components demanding micrometer precision or mass-produced furniture alike, automated accuracy boosts production while ensuring stringent quality standards. The adaptable, data-driven nature of CNC machining resonates highly with modern industrial strategies.

Future of CNC Machining

The future of CNC technology is intensely exciting as innovations promise to continuously enhance these machines. Developments in artificial intelligence, automation, and integrated sensors will allow machines to self-optimize. With AI, programming and calibration may become nearly effortless. Advanced sensors monitoring tools and parts will allow for real-time process corrections to maximize precision.As interfaces unite with the industrial internet of things, types of CNC machines will gain an even deeper understanding of production flows. Machines may predict maintenance needs or rapidly respond to disruptions. Connected data platforms will optimize resources across entire manufacturing ecosystems.

Materials science will surely inspire novel CNC techniques. Whether high-performance plastics or specialty alloys, imaginative pairings of substance and shaping will emerge. Revolutionary machining may transform fields like aviation, space and ocean exploration. The more our comprehension of nature’s marvels expands, the more CNC evolves to keep pushing boundaries. Invention begets invention, as relentless betterment unlocks infinite opportunity.

Conclusion

In conclusion, all the types of CNC machines are very cool tools that help make things. The different machines each do their own jobs to cut stuff in special ways. Some machines like mills and routers work with wood, plastic and metal. Others like lasers and plasma cutters help make neat shapes fast.

There are even machines that can make 3D shapes or designs. They have more axes to move in different directions. The more axes a machine has, the harder shapes it can make. But all machines use computer programs to tell them what to do step-by-step. This helps them cut super accurate without mistakes.People use types of CNC machines for all sorts of projects. Doctors and spaceships need the tiny parts they make. Boats and buildings also need machine parts. Factories even use them to make toys and furniture faster. As machines get smarter with computers, they will be able to do more neat things too!

In the future, new materials might need different kinds of machines. Programmers will add new codes so machines stay helpful. Whatever happens, types of CNC machines will keep changing how people build cool things. Their different jobs let engineers and makers create whatever they imagine. So CNC machines rock

FAQs

Q) What kind of materials can be processed by CNC machines?

CNC machines can work with metals, wood , plastics, composites and more. Depending on the type of material, the type of machine and tools that should be employed also varies.

Q) Is CNC machining expensive?

While CNC machines represent a major investment, they provide efficiencies that can outweigh costs over time by reducing waste and labor compared to manual machining.

Q) What industries utilize CNC machines?

Applications are widespread across aerospace, automotive, medical, energy, furniture making, and more wherever precise, customized parts are needed.

Q) How do I learn CNC machining skills?

Along with hands-on training, many vocational programs and online courses provide instruction for programming, operating, and maintaining various CNC machine types.