CNC utilizes CAD and CAM software to control machine tools to shape complex parts from different materials. Meanwhile, custom CNC machining services encompass many techniques. First of all, CNC milling uses rotary cutters to remove material from the workpiece. It can attain tolerances as tight as ±0.01 mm for precision gears and engine blocks. Next, CNC turning rotates the workpiece on a lathe while a stationary cutting tool shapes it. It suits symmetrical objects, including shafts and bushings, with diameters accurate to within micrometers.

Correspondingly, EDM uses electrical discharges to erode material. It creates convoluted features and close-fitting corners that are challenging for traditional cutting methods. Hence, such processes in machining services CNC milling and custom CNC machining services help produce multifaceted, precise parts in aerospace, medical devices, and automotive industries.

Types of Custom CNC Machining Services

CNC Milling Machining Services

CNC Milling rotate a cylindrical tool to cut materials along multiple axes. Machines can operate on 3 to 5 axes for precision and complexity. For instance, 5-axis milling machines can produce tricky components for aerospace and medical industries with tolerances as tight as ±0.005 mm. Plus, they can execute face, slot, and angular milling with high repeatability. Notably, CNC milling service helps produce prototypes and low-volume production runs of complex geometries. Handling many materials, from titanium to thermoplastics, boosts its versatility.

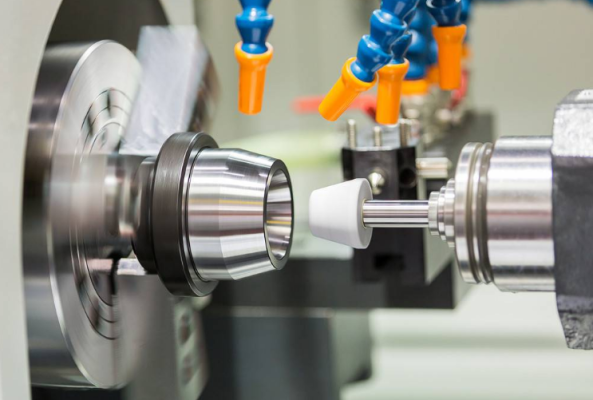

CNC Turning and Milling Machining Parts

CNC turning and milling services combine lathe and milling functions for parts with rotational symmetry and complex details. It helps produce high-precision turbine blades and orthopedic implants. CNC turning on multi-axis lathes machines complex contours and deep grooves. Moreover, the combination with milling operations allows for secondary drilling and tapping without supplementary setups. For example, a CNC lathe with live tooling can manufacture precision gears with a concentricity tolerance of less than 0.01 mm to disregard further finishing.

CNC Vertical Machining Center

CNC vertical machining centers, or VMCs, are key to high-precision and high-efficiency manufacturing. They feature vertically oriented spindles and can accomplish many tasks in one setup, including drilling, tapping, and milling. VMCs suit large, flat plates and dies. Remember, VMCs can realize surface finishes of Ra 0.2 micrometers on aluminum for applications in the semiconductor industry. Their multi-tool capacity and automatic tool changers cut cycle times for productivity. Also, CAD/CAM software offers precise execution of complex part geometries.

CNC Machining Set and Centers

CNC machining centers combine multiple machining processes into a single cell, including milling, turning, and drilling. They handle multifarious and high-volume production with less human intervention. E.g., a Custom CNC Machining center can produce automotive engine blocks with tolerances within ±0.01 mm and surface roughness of Ra 0.4 micrometers. Robotic arms and conveyor systems enable automated operation for maximum throughput. Further, they may include in-process inspection systems for quality control. It avoids post-production inspections.

Custom Turning Milling CNC Machining Nylon Parts

Custom CNC machining services for nylon parts include turning and milling to produce components with good mechanical properties and precision. Nylon is tough, wear-resistant, and ideal for applications in the automotive and electronics industries. CNC machines can produce nylon gears, bushings, and electrical insulators with tight tolerances of ±0.05 mm. The machining process controls cutting speeds and feeds to avoid material deformation and give high-quality finishes. Additionally, CNC machining manufactures threaded inserts and interlocking joints.

Materials Used in Custom CNC Machining

Metals

- Aluminum CNC Machining Parts.

- CNC Machining Stainless Steel.

- Titanium, Copper, Brass, Bronze, Hastelloy, Inconel, Rene alloys, and Waspaloy.

Plastics

- POM, PEEK, UHMWPE, Nylon CNC Milling Machining Parts.

- Plastic Part Custom MC Nylon CNC Machining Parts.

- Based Machined Machining UHMW PE Plastic CNC Part.

- Nylon PTFE CNC Milling Parts CNC Machining Part.

Applications of Custom CNC Machining

CNC Machining Motorcycle Accessories

Custom CNC machining services for motorcycle accessories manufacture sprockets, handlebars, and brake calipers. E.g., CNC-machined aluminum brake calipers can decrease weight for better performance. Also, the machining can reach tight tolerances for engine components and frame brackets. It gives compatibility under high-stress conditions. Besides, CNC machines can create designs that advance the functionality and aesthetics of custom motorcycle parts.

CNC Machining Aluminum Camera Parts

Custom CNC Machining produces high-precision aluminum lens housings, mounting brackets, and sensor enclosures for cameras. The components may require strict tolerances for alignment and focus. For example, CNC-machined aluminum lens housings can improve thermal stability to keep image quality in erratic temperatures. Likewise, the process can produce geometries for ergonomic designs and integrated cooling channels for better usability of professional-grade cameras.

Machined Custom CNC Parts for Various Industries

Custom CNC machining services outfit many industries, from aerospace to medical devices. In aerospace, CNC-machined titanium parts offer a strength-to-weight ratio for aircraft performance. It helps address strict regulatory standards. For medical, CNC machines may produce stainless steel surgical instruments with surface finishes as smooth as Ra 0.4 µm for lower tissue damage during procedures. What is more, automotive industries employ CNC machining for engine components that must endure high temperatures and pressures for vehicle dependability.

CNC Machining Parts for Specific Use Cases

For UHMWPE, POM, Nylon, PEEK CNC Machining Spare Parts: Well, CNC machining creates high-performance parts from UHMWPE, POM, Nylon, and PEEK. They are used in applications demanding low friction and high wear resistance. For example, PEEK parts can survive unceasing operating temperatures up to 260°C for aerospace and chemical processing. UHMWPE’s low coefficient of friction (as low as 0.1) suits bearings and sliding components. CNC machining controls dimensions and tolerances, so high-performance plastics fulfill application requirements.

Advantages of Specific CNC Machining Processes

CNC Mill Machining Center

CNC mill machining centers create complex parts with tight tolerances and tricky geometries. For instance, the 5-axis CNC mills can simultaneously move along multiple axes. It produces parts with compound angles and undercuts in a single setup. The machines attain tight tolerances in aerospace and medical devices. Moreover, handling a range of materials—from hardened steels to exotic alloys like Inconel and titanium—guarantees flexibility in manufacturing applications.

Handle CNC Machining Parts with Precision

Handling Custom CNC Machining parts with precision uses progressive inspection techniques and equipment. CMMs are key here, so parts meet exact specs. For example, in automotive, engine blocks must follow strict tolerances for ideal performance. Laser scanning and high-resolution imaging also heighten the precision of part verification. It cuts the margin of error to nearly zero. So, it guarantees each component fits correctly and functions dependably under severe situations.

Parts CNC Machining Block Parts

Machining block parts using CNC helps create components from solid blocks of material, which decreases internal stresses and increases structural integrity. It benefits parts necessitating high reliability, including aerospace brackets and heavy-duty machine components. With trochoidal milling, material removal rates can be adjusted for lower cycle times. Furthermore, high-speed spindles and toolpath algorithms improve surface finishes for high-precision assemblies.

For premium-quality custom CNC machining services provider, contact Mxy Machining