CNC has been integrated into a variety of new technologies and machines. One such machine, used for a variety of production processes, is a so-called CNC lathes.

Where are CNC lathes used?

There are numerous applications in which a lathe is used. It ranges from industries like automotive, electronics, aerospace, firearms manufacturing, sports, and many more.

One can use a CNC lathe for cutting out metal and also for making flat surfaces and threads.

There are also CNC lathes for embellishments which are specially designed to work on intricate designs such as 3D products.

In a CNC machine, the material is firmly held in place using clamps and collets. A lathe is also used for metalwork, wood turning, and even glasswork.

Some products you can make with a CNC lathe include:

● Signs and boards

● Instruments and musical instruments

● Crankshafts

● Rifle barrels

● Bowls

● Baseball bat

● Dining room tables and chair legs

What are the Key components of CNC lathes?

A lathe consists of several parts that are attached. A properly assembled lathe is very important because there is a lot of resistance from heavy metals when operating a lathe.

Let’s take a look at the important parts of the CNC Lathes:

Stand and legs of the lathe

Since the CNC Lathes has to work with many different materials, it needs to be flexible enough to withstand all of this resistance, and this is where strong lathe legs come in.

A lathe leg holds the machine in a fixed position and they are equally important for flexibility when it comes to adjusting the working height.

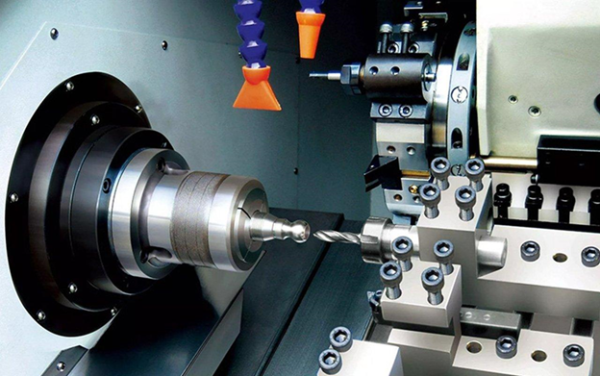

Spindle

The head section houses a spindle that is attached to a tube, which in turn is connected to the chuck.

The chuck holds the workpiece and also spins it around according to the requirements of the final product. There is even a formula to determine the spindle’s cutting speed.

● 4xSFM/ D = RPM

● SFM = cutting speed

● RPM= revolutions per minute

● D= diameter of the workpiece in inches

Transmission

A gearbox is the part of the local CNC machining services that is responsible for controlling the speed of the motors. It is housed in the head and rotates the chuck.

Counter Spindle

The counter spindle is located opposite the spindle. It is a movable part of the CNC machine and can be changed depending on the requirements of the finished product.

The counter spindle consists of a drum that can move either forward or backward. The drum can also be used to support the material.

Sleds

The carriage rotates either in the right or left direction and consists of the saddle, the composite beam, the cross slide, and the top slide. It is an important tool that helps in assembling the toolbar.

Saddle

The saddle is located above the carriage of a CNC Lathes and helps the cross slide to move forward or backward on a lathe. It is usually shaped like an H.

Sliding Piece

The slide supports the tool column and is a useful component when machining materials that require sharp angles. It sits above a cross slide and helps with pivoting.

Cross Slide

Similar to the slide, the cross slide is located above the carriage and moves back and forth on the saddle. You can use the cross slide to engrave on hard metals with the control wheel.

Tool Post

The tool holder is located above the slide and is used to clamp your engraving tool.

Lead screw

The lead screw is a long, shaped rod that has a thread and is located on the machine bed. This is a very helpful part of the CNC Lathes that helps the automatic feed of the slide from the head to the end of the workpiece.

It is mainly responsible for machining the threads on the workpiece.

What different types of spindles are there in CNC machining?

CNC machining are generally divided into two types: vertical lathes and horizontal lathes.

CNC Vertical Lathe

In a CNC vertical lathe, the workpiece rotates in an upright position, similar to what you would see when a potter moves the potter’s wheel, it allows the spindle to cut at hard-to-reach angles and positions.