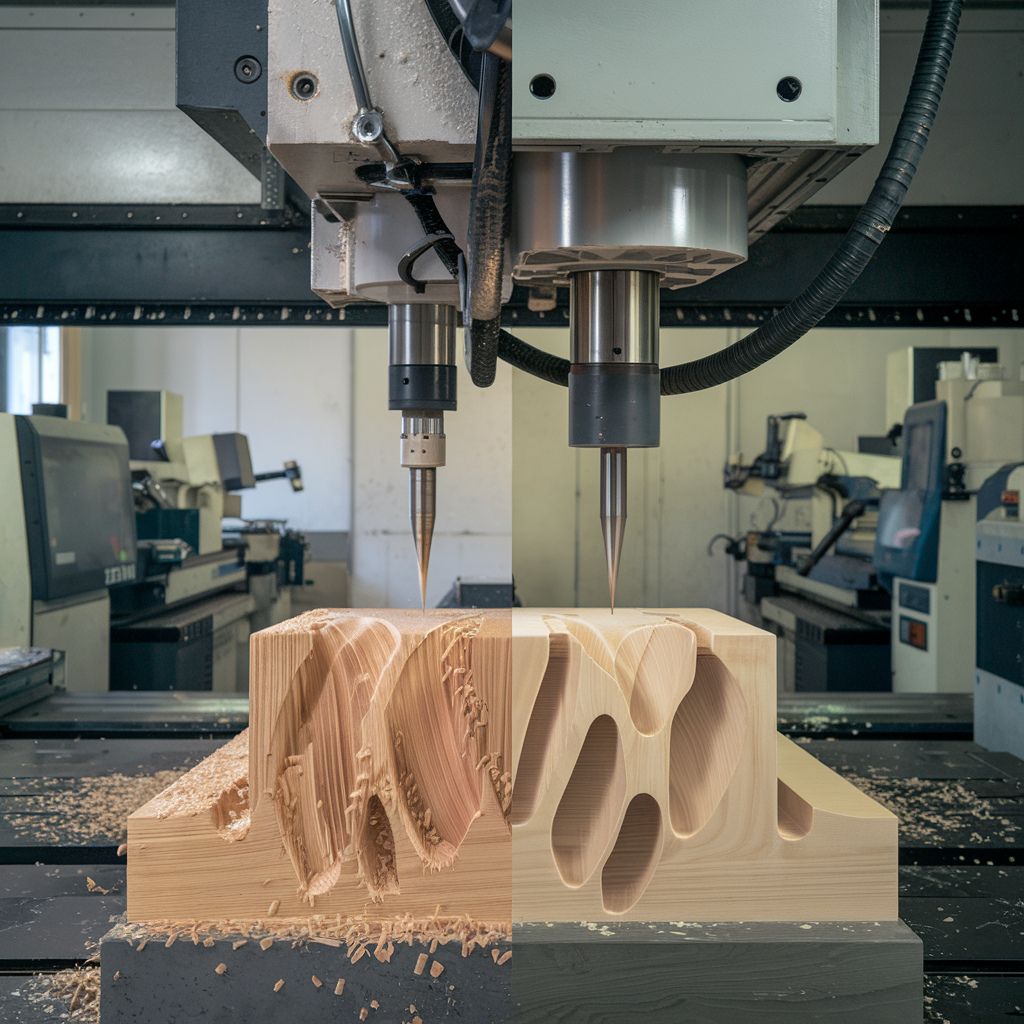

MXY Machining supports the automotive industry with cutting-edge CNC machining solutions, enabling the production of complex parts that drive efficiency and innovation in vehicle systems and processes.

We guarantee that our manufacturing partners follow ISO 2768 standards for all CNC machined parts. Parts machined with metal will follow ISO 2768-m (medium) or ISO 2768-f (fine). Parts machined with plastics will follow 2768-m (medium). Geometric tolerances down to ± 0004 in. (0.010 mm) are possible but must be clearly indicated in technical drawings. We can achieve tighter tolerances on shafts with up to H7 fits with manual quoting and on occasion tighter.