Discover the true 3D Printer Cost, from budget-friendly models to advanced industrial machines. Learn what factors affect prices and find the best fit for your needs.

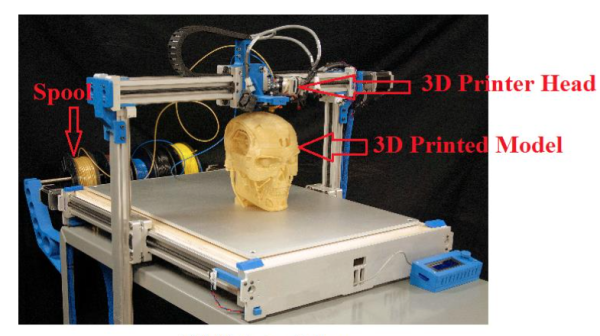

A 3D Printer: What Is It?

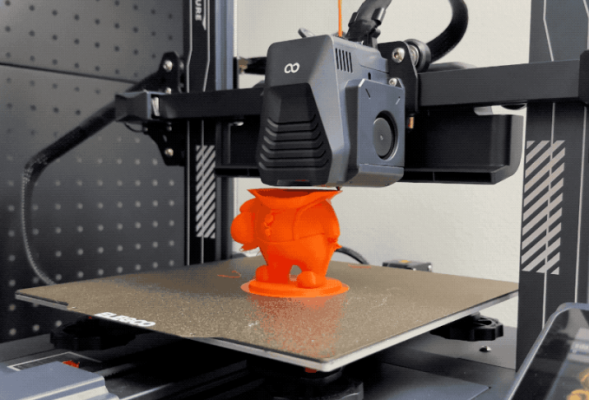

How much is a 3d printer Is defined as a very modern machine that converts digital design into something physical. 3D Printers: 3D printers differ from standard units that produce pictures on paper. Typically driven from a digital 3D model, which is often created using CAD software. These thin horizontal layers of the model are what a 3D printer uses as direction for building an object, making one slice on top of another and moving in vertical steps until all slices have been completed.

3D Printer Cost have been a game changer due to their accuracy and flexibility across different industries, such as manufacturing or healthcare (helping fabricate intricate prototypes and tailor-made parts for medical implants). These days, everybody coordinates with one another and handles the 3D Printer at home, so obviously, ongoing revelations have consistently been there to make you think about what this thing is in light of Modern Technology if we are talking.

A 3D Printer Cost: The Purpose of 3D Printing

Beyond the act of creating something, 3D printing cost is about innovation and customization. Adopting 3D printing enables product designers and engineers to prove their concepts within a very short time period. In industries such as manufacturing, this tech is key in the production of intricate parts that would be impossible or prohibitively expensive to make by regular means.

Among its many vast forwards in the medical space, customized 3D printing allows for the creation of personalized implants, prosthetics, and tissue models specific to individual patients. Hobbyists and artists also use 3D Printer Cost to create one-of-a-kind personal items, from jewelry to home décor. This kind of click-of-a-button custom object-production service symbolizes 3D printability at its most versatile and all-encompassing.

Costs and Features for Finding Your Best 3D Printer

Getting the perfect 3D Printer Cost for your work or DIY project can be challenging. There are different models, from cost-effective to fully-fledged industrial ones, and it is important to know the price each type of machine offers. MXY Machining can help you make the right choices that are tailored to your specific needs.

Our in-depth guide will walk you through how 3D printing can be used for various applications, from producing fine models and molds to developing individualized surgery tools. What determines the cost of a 3D Printer Cost, including material types, print resolution, and production speed? Whether you’ve just started researching or have been scouring the web for days, knowing the importance factors will help guide you in choosing a 3D printer that fits your needs.

At MXY Machining, we are proud to offer our expert knowledge and cutting-edge technology to meet your 3D printing requirements. Make the most of 3D printing, CNC machining, and great finishing from MXY Machining for your idea—just visit our official site to learn more about choosing the right printer.

A 3D Printer: How Much Does It Cost?

The 3D Printer cost can vary widely depending on several factors, making it important to consider what you’re looking for before purchasing. Here are some key points to consider when evaluating the cost of a 3D printer:

Entry-Level 3D Printers:

- Typically priced between $200 to $500.

- Ideal for beginners and hobbyists.

- Features are basic but sufficient for simple projects.

- These printers often use FDM (Fused Deposition Modeling) technology, which is affordable and easy to maintain.

Mid-Range 3D Printers:

- Priced between $500 to $2,000.

- Suitable for more advanced users or small businesses.

- Offer better build quality, higher resolution, and more material options.

- Includes features like heated beds, larger build volumes, and sometimes dual extrusion.

High-End 3D Printers:

- Range from $2,000 to over $10,000.

- Designed for professional use in engineering, architecture, and healthcare.

- High precision, larger build volumes, and the ability to print with specialized materials like metal or resin.

- Often include advanced features like automated calibration, closed-loop systems, and higher printing speeds.

Industrial 3D Printers:

- Can cost anywhere from $10,000 to over $100,000.

- Used in large-scale manufacturing and specialized industries.

- Capable of producing large parts with high precision using various materials.

- These printers often use technologies like SLS (Selective Laser Sintering) or SLA (Stereolithography), which offer superior quality and performance.

- The 3D Printer cost ultimately depends on your needs, whether it’s for personal projects, professional work, or industrial manufacturing. Understanding these categories will help you decide based on your budget and the required features.

A 3D Printer: Factors Affecting the Price

When considering the purchase of a how much is a 3d printer cost, it’s essential to understand the various factors that influence its price. Here are the key factors that determine how much a 3D printer will cost:

- Technology Type:

- FDM (Fused Deposition Modeling): Generally more affordable, with prices ranging from $200 to $2,000. It’s suitable for beginners and hobbyists but may have precision and material options limitations.

- SLA (Stereolithography): Priced higher, typically starting at $1,000 and going up to $10,000 or more. It offers higher resolution and is used for detailed prints in industries like dentistry and jewelry.

- SLS (Selective Laser Sintering): Among the most expensive, often starting at $5,000 and reaching well over $50,000. This technology is used in industrial applications to create high-strength, complex parts.

- Build Volume:

- Printers with larger build volumes tend to be more expensive.

- A larger build volume allows for printing bigger objects in a single piece, which is particularly important for industrial applications.

- Material Compatibility:

- Printers that can handle a wide range of materials, such as metal, carbon fiber, or flexible filaments, tend to cost more.

- Specialized materials often require specific printer features, like heated beds or enclosures, which add to the overall cost.

- Precision and Resolution:

- Higher precision and finer resolution in printing lead to more expensive printers.

- Precision is critical for applications requiring detailed and accurate models, such as engineering and medical.

- Brand and Support:

- Established brands with a reputation for quality and reliability typically charge a premium.

- Additionally, printers that come with robust customer support and warranty options are usually priced higher.

- Advanced Features:

- Features like automated bed leveling, dual extrusion, wireless connectivity, and touchscreen interfaces can significantly increase costs.

- These features enhance user experience and printing efficiency, making them desirable for more serious users.

Understanding these factors will help you make a more informed decision, ensuring that you choose a 3D Printer Cost that meets your needs without overspending.

A 3D Printer: Comparing Prices Across Different Models

A 3D Printer: Comparing Prices Across Different Models

When comparing 3D Printer Cost, understanding the different technologies available is crucial, as each type offers distinct advantages and comes at varying price points. Here are some of the primary 3D printing technologies used by MXY Machining:

- Fused Deposition Modeling (FDM): This is one of the most affordable options, with entry-level models starting around $200. FDM printers are suitable for basic prototypes and functional parts.

- Stereolithography (SLA): SLA printers generally start around $3,000 and are known for their high precision and fine details, making them ideal for intricate models and professional applications.

- Selective Laser Sintering (SLS): SLS printers, depending on their size and capabilities, are typically priced between $5,000 and $100,000 or more. This technology is excellent for creating durable parts with complex geometries.

- PolyJet: Often used for multi-material and multi-color printing, PolyJet printers can cost between $10,000 to $100,000, depending on the model. These are commonly used in industries that require detailed and versatile prototypes.

- Metal 3D Printing is one of the most expensive technologies, with prices ranging from $50,000 to several hundred thousand dollars. It is ideal for producing strong, functional metal parts for industrial applications.

By comparing these technologies, you can determine which type of 3D Printer Cost best suits your needs and budget, whether you’re looking for an entry-level model or a high-end industrial solution.

A 3D Printer: Is It Worth the Investment?

Investing in a 3D Printer Cost, especially through a service like ours, can significantly enhance your manufacturing capabilities. We offer advanced 3D printing technologies such as Metal 3D printing, PolyJet, SLA, and SLS, each tailored to meet diverse industrial needs. The key benefits include reduced production costs, faster turnaround times, and the ability to create highly detailed and complex parts on demand. For businesses looking to innovate and streamline their production processes, our 3D printing services provide a robust and cost-effective solution.