What is powder metallurgy, learn the basics, process involved, uses and advantages of powder metallurgy. Analyses how the application of powder metallurgy gears and components is rapidly changing manufacturing.

What is Powder Metallurgy?

Powder metallurgy is a manufacturing process by which metal powders undergo a process of heating and then pressing to from a solid metal. It can be used in production of components which may be very challenging or expensive to be manufactured by using conventional processes. The PM technique offers improved control of material characteristics, further, it is generally cheaper metal-working option particularly for large and intricate shapes as well as large scale production.

How Does Powder Metallurgy Work?

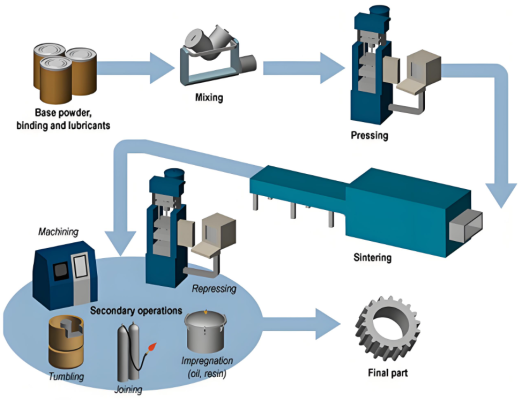

The process of powder metallurgy involves several key steps:

1. Powder Production

The first of these is the generation of metal powders, which is an important step of the powder metallurgy. These powders can be created using several methods:

- Atomization: This is by far the most commonly used technique that employs the use of a high-pressure gas or liquid medium to splash molten metal into fine droplets. These droplets cool hyper first and becomes powder like solid particles.

- Reduction: It is a technique in which metals oxides are brought back to their metallic form by the reduction with a chemical agent such as hydrogen or carbon yielding fine powders of metals.

- Electrolysis: This process of electro refining involves the passage of an electric current through a metal solution so as to electro deposit the metal as fine powder or small particles. These particles are then collected and processed into powder which is used again for the production of surgical instruments.

Both methods create different types of powders in terms of size and shape of the particles and thus impact the final part that has been manufactured.

2. Blending

After the metal powders’ forming, they are mixed with other substances or materials like lubricant or the elements of an alloy to get the necessary characteristics for the consequent part. This process of blending effectively ensures that the materials are well distributed throughout and this plays a great role in the performance of the final good. The blending also assists in the reduction of flowability at the same time enhancing the ease at which the obtained powder mixture can be compacted during the subsequent step.

3. Compaction

The final step in the palletizations process is compaction where the blended powder is put in a mold or die then pressed to the shape required is obtained by application of pressure. This is done with the help of a machine called as the powder metallurgy press. Thus, the goal of compaction is to produce a green compact, a milled part that can be gripped but is not yet the finished object. The pressure, which is exerted during compaction, defines the density of a certain mechanical characteristic of the final part.

4. Sintering

Sintering is an important process in the Subject-PM, where the green compact is exposed to heat in a medium and most of the time in a sintering furnace. The process is managed carefully to ensure that the temperature does not exceed the melting point of the major metallic constituent and in this way, particles are joined by diffusion. Sintering takes place in which the part is slightly reduced in size due to the fusion of particles and thus improves the strength and density of the part. The state of matter present within the furnace (that might typically include inert or reducing gases) is manipulated so as not to compromise the metal through oxidation.

5. Finishing

If required, that part may go through one or more refining processes for meeting the required standard after the sintering has been performed. These finishing steps can include:

- Machining: To enhance the stability, quality and detail of the dimensions of a workpiece or to produce required features such as holes and threads.

- Sizing: Additional force applied on the part to make it acquire the desired dimensions.

- Coating: Application of a thin layer of coating to improve on the surface performance characteristics.

- Heat Treatment: in order to improve more mechanical characteristics like hardness or toughness of material.

Such finishing techniques are important in an endeavor to ensure the produced part or product attains the necessary standard for its purpose of use.

In conclusion, powder metallurgy can be viewed as a universal and effective manufacturing technique that enables creating intricate shaped parts made from a wide range of materials, using the required characteristics of end products.

History of Powder Metallurgy

Powder metallurgy began thousands of years ago when, for instance, early man cast mementos and forged tools and weapons with crude methodologies. In the 19th century towards the more marked advancement of electric power in the industry the new period of powder metallurgy set in. Several years ago, this process has undergone through experiences mainly due to technology and material science and has become widely applied in industries today.

Materials Used in Powder Metallurgy

Powder metallurgy can thus involve the utilization of materials that are diverse depending on the application to be made. Some of the most common materials include:

- Iron and Steel: Structural parts, gears and car components, sintered or infiltrated with copper or a copper alloy.

- Copper and Copper Alloys: Popular in the electrical circuits.

- Aluminum: Highly appreciated for its low density, it is normally employed in aerospace as well as automotive applications.

- Tungsten: Recognized for its ability to melt at high temperatures and the density it has in various applications such as heavy duty.

- Titanium: Has a good strength to weight ratio and is resistant to corrosion and is used in such items as medical implants and aerospace applications.

Range of Applications

Powder metallurgy is used in almost all divisions and is not specific to any field. Some key applications include:

- Automotive Industry: PM gears, bearings and other parts used are tough and accurate because of the process they have undergone.

- Aerospace Industry: Powder metallurgy components are light for their strength, thus can be used in aircrafts and spaceships.

- Medical Industry: Powder metallurgical application is utilized in manufacturing of biocompatible implants and surgical tools.

- Electrical Industry: Most of the P/M product consists of electrical contacts, magnetic parts, and heat exchangers.

- Tools and Hardware: Because this process produces a surface which is harder and more wear resistant, cutting tools, powder metallurgy blades and other tools can be made from it.

Advantages and Disadvantages of Powder Metallurgy

Advantages

- Material Efficiency: As little waste as possible as leftover powder can be used again.

- Complex Shapes: Freedom to do complicated shapes not possible to achieve with conventional techniques.

- Cost-Effective: Mostly it is suitable for the production of a large number of products, known as high-volume production runs.

- Controlled Porosity: Can be used in creating products that can self-lubricate themselves.

Disadvantages

- High Initial Costs: Highly expensive in tooling and machines, therefore not suitable for first-time-low-repetition kind of production.

- Material Limitations: Some materials cannot be used in powder metallurgy processes, seems very fragile and weak.

- Density Variation: Localized presence of components can have diverse density and therefore could stress up different properties across regions in the part.

Why We Prefer Mxymachining for Powder Metallurgy Services?

In DMG’s powder metallurgical operations, therefore, choosing an appropriate partner for the process is fundamental. Mxymachining stands out in the industry due to its:

- Advanced Machinery: Having latest powder metallurgy equipment’s and press required for the production.

- Experienced Team: Competent and well-trained team that has the knowledge of how powder metallurgy process works.

- Custom Solutions: More flexibility to simultaneously satisfy both the needs of the customers and the business.

- Quality Assurance: Sourcing of high-quality material that will meet our high standards of quality control.

Conclusion

As observed, powder metallurgy is an exciting and diverse manufacturing technology most industries cannot do without. PM materials find prospects in automotive industries, aerospace industries, medical industry electrical applications and many others since PM has its own unique strengths that other methods cannot mimic. When it comes to the negative aspects that are characteristic for this process, it is important to understand that they are much less pronounced compared to the advantages of such cooperation, especially in case the cooperation is to be arranged with a reliable supplier like Mxymachining.

FAQs

1. What is the main advantage of powder metallurgy?

The main benefit of powder metallurgy is the possibility of creating products with rather complicated and unusual shapes at relatively low losses; therefore, this method is perfect for mass production.

2. What materials are commonly used in powder metallurgy?

Some of these materials are iron, steel, copper, aluminum, tungsten, and titanium which are preferred depending on the use that the wire is going to be put to as well as the properties possessed by the wire.

3. How does sintering work in powder metallurgy?

Sintering is the process by which the compacted powder is heated in a furnace just below its melting point and the particles fuse to from the required solid part without melting.

4. Why choose Mxymachining for powder metallurgy services?

Mxymachining has high-tech equipment, experienced staff, individual tailor-made solutions, and high-quality control, make it firstly pick in powder metallurgy service industry.

5. What industries benefit most from powder metallurgy?

The automotive, aerospace, medical, and electrical industries have been most advantaged by the precision, efficiency, and cost advantages of powder metallurgy.