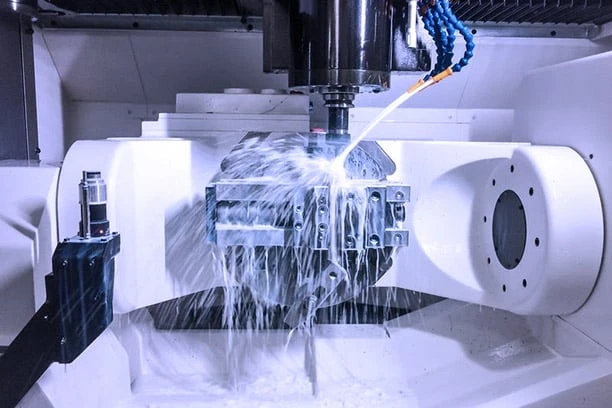

When it comes to prototyping, CNC machining stands out for its precision and versatility. You can create parts with tight tolerances and exceptional accuracy, making it ideal for industries like aerospace, automotive, and medical. One of its biggest advantages is the wide range of materials you can use. Metals like aluminum, stainless steel, and titanium are popular for their strength and durability. Plastics such as ABS and PEEK offer lightweight options with excellent resistance to wear. Whether you need a durable prototype or a lightweight design, Обработка с ЧПУ gives you the flexibility to meet your project’s demands.

Advantages of CNC Machining for Prototyping

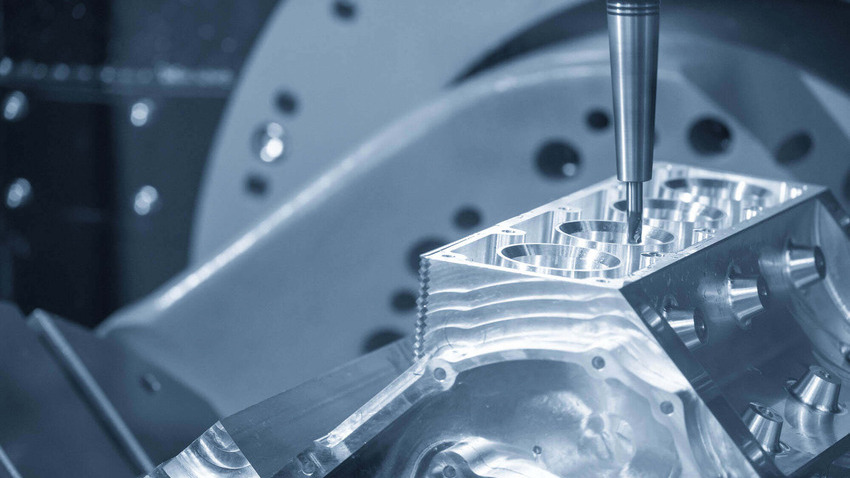

Точность и аккуратность

When you’re working on a prototype, precision can make or break your project. CNC machining excels in this area, delivering tolerances as tight as 0.01 millimeters. This level of accuracy ensures that your prototype matches your design specifications perfectly. Skilled operators can push these tolerances even further, achieving results that are nearly impossible with other methods.

Industries like medical and defense rely heavily on this precision. For example:

- Медицина: Devices like surgical tools and implants demand impeccable accuracy to ensure safety and functionality.

- Военное дело и оборона: Components must meet strict standards for durability and performance.

- Электроника: Small, intricate parts require high fidelity to function correctly.

With CNC machining, you can trust that every detail of your prototype will be spot-on.

Универсальность материала

One of the standout features of CNC machining is its ability to handle a wide range of materials. Whether you’re working with tough metals or advanced composites, this method has you covered. Here’s a quick look at some materials it can process:

| Тип материала | Characteristics |

| Hard-to-Machine Metals and Alloys | Titanium, Inconel, Stainless Steel 304 and 303 – known for hardness and toughness, difficult to machine manually. |

| Engineered Plastics | PEEK, Polycarbonate – tough materials requiring precise control during machining. |

| Advanced Composites | Carbon Fiber Reinforced Plastics – directional strength makes manual machining problematic. |

This versatility means you can create prototypes that are not only functional but also tailored to your specific needs. Whether you need a lightweight plastic part or a durable metal component, CNC machining offers the flexibility to bring your ideas to life.

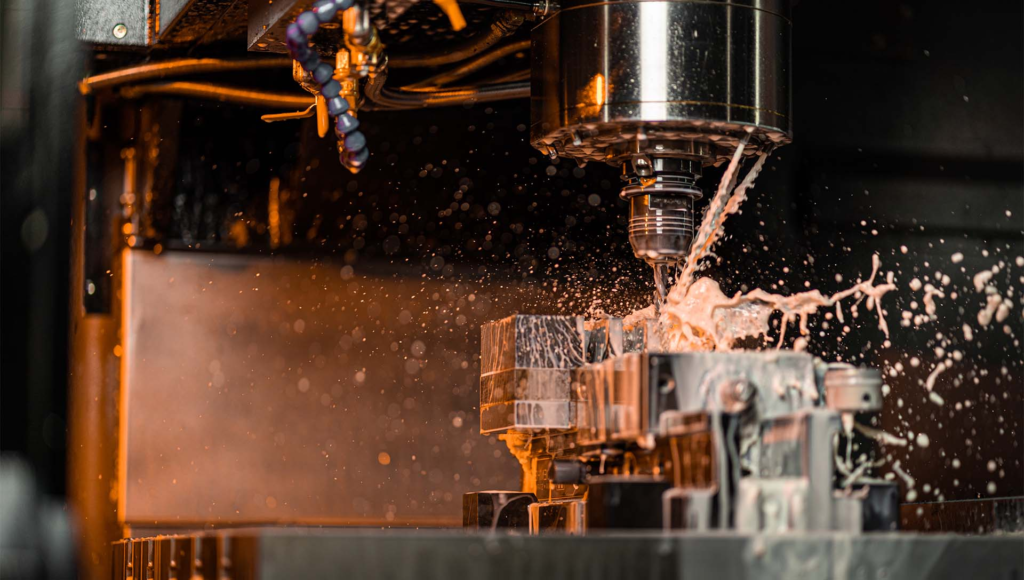

Speed and Rapid Iterations

Time is often a critical factor in prototyping, and CNC machining doesn’t disappoint. It allows you to produce prototypes quickly, enabling rapid iterations and adjustments. This speed is especially useful when you’re testing and refining your designs.

For instance, MXY Machining’s CNC solutions can handle both small and large production runs efficiently. The machines self-monitor for accuracy, ensuring consistent quality even during fast-paced production. This capability makes it easy to scale from a single prototype to a full production run without losing momentum.

If you’re looking to save time while maintaining high standards, CNC machining is a game-changer. You can test, tweak, and perfect your designs faster than ever.

Масштабируемость для производства

When you’re prototyping, it’s not just about creating a single part. You’re often thinking ahead—what happens when you need to scale up? This is where CNC machining shines. It’s not just a tool for one-off prototypes; it’s a powerhouse for scaling production without missing a beat.

CNC machining makes it easy to move from a prototype to a full production run. Once you’ve perfected your design, the same program used for the prototype can be reused for manufacturing. This eliminates the need to start from scratch, saving you time and effort. Plus, the process ensures consistency. Whether you’re making ten parts or ten thousand, each one will meet the same high standards.

Another advantage is flexibility. Need to tweak your design before scaling up? No problem. With CNC machining, you can make adjustments to the digital file and produce updated parts quickly. This adaptability is a game-changer, especially in industries where designs evolve rapidly.

You’ll also appreciate the efficiency. Modern CNC machines, like those used by MXY Machining, are built for speed and precision. They can handle large production runs while maintaining tight tolerances. This means you can scale up without sacrificing quality. And because the machines are automated, you’ll reduce the risk of human error, keeping your production process smooth and reliable.

In short, CNC machining bridges the gap between prototyping and production. It gives you the tools to grow your project, whether you’re producing a handful of parts or scaling to mass production. If scalability is on your mind, this method has you covered.

Limitations of CNC Machining for Prototyping

Higher Costs for Small Budgets

CNC machining can be expensive, especially for small-scale projects. If you’re working with a tight budget, this might not be the most cost-effective option. The setup process involves programming and tooling, which can drive up initial costs. While CNC machining becomes more affordable as production scales up, smaller runs often don’t benefit from these economies of scale.

For instance, 3D printing maintains consistent costs regardless of the number of prototypes. In contrast, CNC machining’s cost per unit decreases as you produce more parts. This means that for a single prototype or a small batch, you might find CNC machining pricier than other methods. If you’re looking to save money on a small project, it’s worth considering whether the precision and material options justify the higher expense.

Complexity in Setup and Programming

The setup and programming process for CNC machining can be tricky. Even small errors in the code can lead to defective parts or damage to the machine. You’ll need skilled operators to handle the programming and ensure everything runs smoothly.

Here are some common challenges you might face:

- Programming errors that result in flawed products.

- Machine vibration, which can reduce tool quality and part durability.

- Output imperfections like rough edges or cutter marks due to improper settings.

- Overheating from continuous operation, which affects both tools and materials.

- Choosing the wrong material, which can complicate the machining process.

- Using an incompatible power supply, which impacts machine efficiency.

These issues highlight the importance of expertise and attention to detail. If you’re new to CNC machining, the learning curve might feel steep.

Challenges with Complex Geometries

CNC machining isn’t always the best choice for intricate designs. The tools have physical limitations, which can make it hard to create certain features. For example, undercuts or detailed internal structures often pose challenges. The tools might not be able to reach certain areas, or their movement could be restricted.

If your prototype involves highly complex geometries, you might need to explore alternative methods. Techniques like 3D printing can handle intricate designs more effectively, thanks to their layer-by-layer approach. While CNC machining excels in precision and durability, it’s not always the right fit for every design.

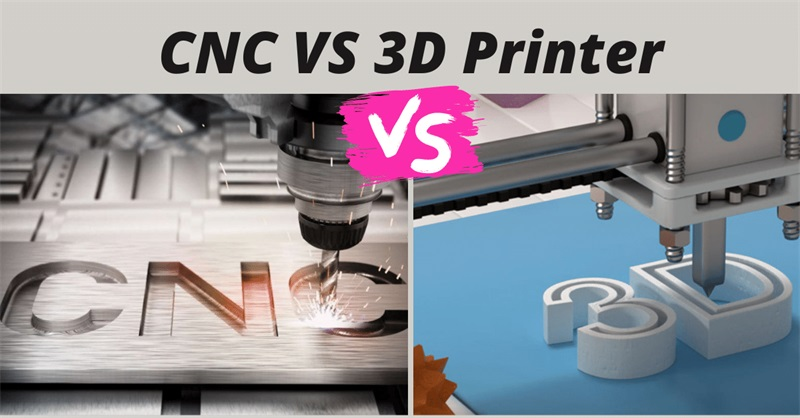

CNC Machining vs. Other Prototyping Methods

CNC Machining vs. 3D Printing

When deciding between CNC machining and 3D printing, precision and finish are key factors. CNC machining delivers unmatched accuracy, with tolerances as tight as 0.005 mm under optimal conditions. This results in parts with a polished, professional look. On the other hand, 3D printing often struggles with visible layer lines, especially on curved surfaces, and tolerances typically hover around 0.2 mm.

| Attribute | 3D-печать | Обработка с ЧПУ |

| Точность | 0.016 mm to 1 mm+ (varies) | 0.005 mm (optimal conditions) |

| Surface | Layer lines, potential warping | Smooth, polished finish |

If your project demands high precision or a flawless surface, CNC machining is the better choice. However, 3D printing shines when creating intricate designs or prototypes with internal structures that CNC tools might struggle to reach.

CNC Machining vs. Injection Molding

Cost and production volume often dictate whether you choose CNC machining or injection molding. CNC machining has lower upfront costs, making it ideal for low to medium production volumes. You’ll save on tooling expenses since injection molds can cost thousands—or even hundreds of thousands—for complex designs. As production scales up, though, injection molding becomes more cost-effective due to its efficiency in high-volume runs.

That said, CNC machining offers flexibility. You can tweak designs easily without creating new molds, which is perfect for iterative prototyping. Injection molding, while efficient, lacks this adaptability and requires significant investment before production even begins. If you’re working on a smaller scale or need design flexibility, CNC machining is the way to go.

Choosing the Right Method for Your Project

So, how do you decide? Start by evaluating your project’s specific needs. Consider factors like production volume, material requirements, and design complexity. CNC machining excels in low to medium volumes, especially when precision and durability are critical. If your design involves intricate geometries or internal structures, 3D printing might be a better fit. For large-scale production of plastic parts, injection molding offers unmatched efficiency.

Also, think about your budget and timeline. CNC machining provides a balance of speed and quality, making it a versatile option for many projects. If you’re unsure, consult with experts like MXY Machining to explore the best solution for your needs. They can help you weigh the pros and cons based on your unique requirements.

Best Applications of CNC Machining in Prototyping

Industries That Rely on CNC Machining

You might be surprised by how many industries depend on CNC machining for prototyping. Its precision and efficiency make it a go-to solution for creating complex parts that meet strict specifications. Here are some industries where this technology plays a vital role:

- Аэрокосмическая промышленность: Aircraft components must perform flawlessly under extreme conditions.

- Автомобили: Prototypes for engines, transmissions, and safety systems demand high accuracy.

- Медицинские приборы: Surgical tools and implants require impeccable precision for safety and functionality.

- Электроника: Small, intricate parts like circuit boards rely on CNC machining for accuracy.

- Морской: Durable components for harsh underwater environments are often prototyped this way.

- Нефть и газ: Equipment used in drilling and extraction needs to withstand high stress.

- Защита: Military-grade parts must meet exacting standards for reliability.

- Потребительские товары: Everyday products like appliances and gadgets benefit from rapid prototyping.

These industries rely on CNC machining because it delivers consistent quality, supports customization, and scales easily for production.

Examples of Successful Prototyping Projects

CNC machining has been behind some pretty exciting prototypes. For example, advancements in human-robot interaction in vehicles have been made possible through this technology. One notable project involved a gestural interface that enhances user experience, making driving safer and more intuitive. Another standout is Honda’s E prototype. This innovative design features pop-out handles and compact wing mirrors that double as cameras. These examples show how CNC machining can bring cutting-edge ideas to life with precision and style.

Scenarios Requiring High Durability and Precision

Certain situations demand prototypes that can handle extreme conditions. Aerospace is a prime example. Components like turbine blades or structural parts must function perfectly in high-stress environments. In these cases, even the smallest flaw could lead to failure. CNC machining ensures these parts meet exacting standards, minimizing risks. Similarly, industries like defense and oil and gas rely on this technology to create durable prototypes that perform reliably under pressure. When precision and durability are non-negotiable, CNC machining is the clear choice.

CNC machining offers you a reliable way to create prototypes with unmatched precision and material flexibility. Whether you’re testing multiple designs or need components that can handle extreme conditions, this method delivers results you can trust. It’s especially valuable for projects requiring жесткие допуски or durable materials, like those in aerospace or defense.

However, it’s not always the most budget-friendly option. High initial costs and the need for skilled operators can make it less appealing for smaller projects. Still, if accuracy and scalability matter most, CNC machining is hard to beat. Ultimately, your choice should depend on your project’s unique needs and goals.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

What is the typical turnaround time for CNC machined prototypes?

Обработка с ЧПУ is fast! You can get prototypes in as little as a few days, depending on complexity and material. At MXY Machining, we prioritize efficiency, so you’ll have your parts ready quickly without compromising quality. Need it faster? Just ask about expedited options.

Can CNC machining handle custom designs?

Absolutely! CNC machining works with digital CAD files, so you can create highly customized designs. Whether it’s a unique shape or specific dimensions, MXY Machining ensures your prototype matches your vision. Just share your design, and we’ll take care of the rest.

Is CNC machining eco-friendly?

It depends on how it’s used. CNC machining produces waste material, but MXY Machining minimizes waste by optimizing processes. Plus, we recycle leftover materials whenever possible. If sustainability matters to you, let us know—we’ll work to align with your goals.

How do I choose the right material for my prototype?

Think about your prototype’s purpose. Need durability? Go for metals like aluminum or titanium. Want something lightweight? Plastics like ABS or PEEK are great. At MXY Machining, we’ll guide you through material selection to ensure your prototype performs as expected.

Do I need technical expertise to use CNC machining?

Not at all! You don’t need to be an expert. Just provide your design and requirements. MXY Machining’s skilled team handles the technical details, from programming to production. We make the process simple and stress-free for you.