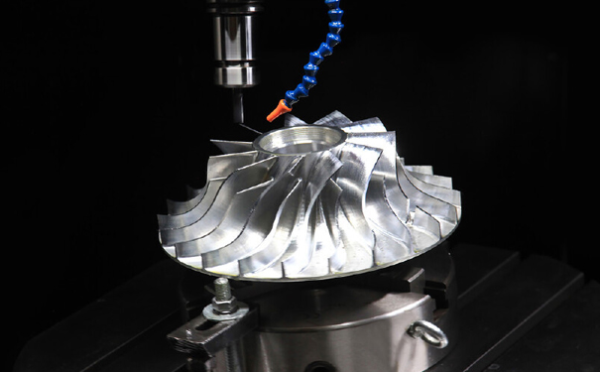

5-assig CNC bewerken maakt gebruik van X, Y en Z lineaire assen, samen met A en B rotatieassen. Het maakt nauwkeurig, gelijktijdig CNC snijden in meerdere richtingen mogelijk om complexe geometrieën in CNC bewerkingsproducten beter te produceren. 5-assige systemen kunnen turbinebladen en luchtvaartonderdelen in één enkele opstelling bewerken. De componenten omvatten spindels met hoge snelheid, stappenmotoren voor nauwkeurige besturing en structuren voor stijfheid onder omstandigheden met hoge belasting. Bovendien optimaliseert CAM-software de gereedschapsbanen om de handmatige programmering minder complex te maken en de kwaliteit van de oppervlakteafwerking te verhogen.

Draaitafel en zwenkbare spilkop

Een 5-assig CNC bewerkingscentrum met draaitafel en zwenkbare spilkop biedt 360 graden rotatie van de tafel (B-as) en zwenken van de spilkop (A-as). Deze machine bewerkt onderdelen met veelzijdige geometrieën, waaronder turbinebehuizingen, met veel voorkomende schuine gaten en complexe kenmerken. De precisie voor het boren van vele schuine gaten rond een cilindrisch onderdeel kan bijvoorbeeld bereikt worden met deze opstelling. De mogelijkheid om onmiddellijk te kantelen en te roteren bevestigt dat het gereedschap loodrecht op het snijoppervlak staat voor een grotere nauwkeurigheid en afwerking van het oppervlak.

Dubbele draaitafel

De dubbele draaitafelconfiguratie heeft twee roterende 5-assige CNC bewerkingen op de tafel voor flexibiliteit en complexe positionering. Het kan ringen met meerdere gaten in luchtvaartonderdelen bewerken. Door de rotatievrijheid in te schakelen wordt opspannen en herpositioneren overbodig, voor minder insteltijd en fouten. Zo kan het bewerken van een ring met gaten op een dubbele draaitafel het proces rationaliseren, omdat het gereedschap onder verschillende hoeken kan werken met verwaarloosbare aanpassingen. Dit verhoogt de efficiëntie en precisie.

Tappen Tafel Machine

Bij een draaitafelmachine zijn beide rotatieassen in de tafel ingebouwd. Deze machine maakt ondersnijdingen en complexe contouren voor mallen en matrijzen. De draaitafelconfiguratie helpt bijvoorbeeld bij het maken van gedetailleerde motoronderdelen in de auto-industrie. De mogelijkheid om de tafel te kantelen vergroot de toegankelijkheid tot vele werkstukoppervlakken voor hoge precisie en kortere cyclustijden. Ondertussen biedt de stationaire spindelkop ook meer koppel en stabiliteit voor zware bewerkingen.

Draaibare of scharnierende kop

Zwenk- of knikkopmachines hebben een kop die kantelt en draait in een kop-kop of kop-tafel patroon. Dit helpt machines met grote, zware onderdelen omdat de tafel stationair blijft om het gewicht te ondersteunen. Bij de productie van grote vleugelliggers gebruikt de zwenkkop bijvoorbeeld kortere, stijvere snijgereedschappen voor minder trillingen en een betere oppervlakteafwerking. Bovendien biedt de zwenkkop flexibiliteit, zodat het gereedschap het werkstuk vanuit vele hoeken bereikt zonder het werkstuk te verplaatsen.

Dubbele draaibare hoofdvorm

De dubbele draaikopvorm maakt gebruik van twee rotatieassen om de freesas te besturen. Hij is geschikt voor onderdelen die een hoge precisie en detaillering vereisen. De opstelling kan de medische industrie helpen bij het bewerken van talloze implantaten en chirurgische instrumenten. De dubbele draaibare kop helpt bijvoorbeeld bij het bewerken van geronde oppervlakken en gecompliceerde geometrieën in knie-implantaten. Door de frees 5-assig CNC te besturen, kan de machine zeer nauwkeurig fijne details produceren en nabewerking vermijden.

Nylon, POM, PEEK, UHMWPE CNC Onderdelen die de Diensten machinaal bewerken

Nylon, POM, PEEK en UHMWPE zijn technische kunststoffen met briljante mechanische eigenschappen en bewerkbaarheid. PEEK is bijvoorbeeld temperatuur- en chemicaliënbestendig voor ruimtevaart en medische toepassingen. UHMWPE biedt slijtvastheid en lage wrijving voor slijtvaste onderdelen. 5-assig CNC verspanen van dergelijke materialen vereist een nauwkeurige gereedschapsselectie, inclusief hardmetalen of PCD gereedschappen, om strakke toleranties en gladde afwerkingen te behouden. Bovendien voorkomt het beheersen van de warmteontwikkeling tijdens het bewerken materiaalvervorming en blijft de maatvastheid behouden.

CNC-bewerking van aluminium

5-assige CNC-bewerkingsonderdelen aluminium bieden een goede verhouding tussen sterkte en gewicht, corrosiebestendigheid en bewerkbaarheid. Hoge snelheid CNC-bewerking met spindelsnelheden van meer dan 10.000 omw/min kunnen helpen om ideale oppervlakteafwerkingen en toleranties te realiseren. Kwaliteiten 6061 en 7075 worden gekozen vanwege hun mechanische eigenschappen en bewerkingsgemak. Toleranties binnen ±0,005 inch zijn gebruikelijk voor onderdelen voor de ruimtevaart. Voor de maatnauwkeurigheid zijn instellingen en gereedschapsplanning nodig om de thermische uitzetting te verlagen.

Bewerking, Draaien, Frezen van Plastic Onderdelen CNC

Bij het bewerken van kunststof onderdelen moet rekening worden gehouden met thermische uitzetting en spaanvorming. Pikboren en machinale bewerking met hoge snelheid minimaliseren de warmteontwikkeling om smelten of kromtrekken te voorkomen. Voor precisieonderdelen kunnen materialen zoals ABS en acryl gebruikt worden, met toleranties van ±0,002 inch. Bovendien kunnen koelvloeistofsystemen en scherpe, gepolijste snijgereedschappen de oppervlakteafwerking en standtijd verbeteren voor een betrouwbare kwaliteit bij grote productieruns.

Micro-Verspaningsdienst CNC Bewerkte Onderdelen

Micromachining produceert kleine en lastige onderdelen met afmetingen van 1-500 µm. 5-assige CNC-verspaning met hoge precisie met frezen met diameters van slechts 0,1 mm zijn essentieel. Bovendien omvatten de toepassingen medische, MEMS en wetenschappelijke instrumenten met hoge precisie, maar zijn daar niet toe beperkt. Daar kunnen zelfs de kleinste dimensionale variaties de prestaties beïnvloeden.

CNC Plastic onderdelen machinale bewerking

5-assig CNC verspanen van kunststof onderdelen is van vitaal belang in de auto- en consumentenelektronica. De keuze van het materiaal, waaronder Delrin voor hoge sterkte en slijtvastheid of PTFE voor toepassingen met lage wrijving, bepaalt de bewerking. Frezen met hoge voeding en speciale kunststof snijgereedschappen verhogen de productiviteit en oppervlaktekwaliteit. Bovendien kan gloeien na het bewerken de interne spanningen verlichten voor dimensionale stabiliteit. Dit garandeert dat de onderdelen voldoen aan de specificaties en prestatievereisten.

Aangepaste CNC Aluminium Camera Onderdelen

Aluminium camera-onderdelen vereisen precisiebewerking voor nauw aansluitende geometrieën en toleranties. 5-assige CNC-bewerking met hoge snelheid helpt bij het maken van ontwerpen met toleranties tot ±0,002 inch. Anodiseren is een gebruikelijk nabewerkingsproces voor een betere corrosiebestendigheid en esthetische afwerking. Bewerkingsstrategieën passen de gereedschapsbanen aan om de doorbuiging van het gereedschap te verminderen en een constante koelmiddelstroom te garanderen voor maatnauwkeurigheid en oppervlakte-integriteit over samengestelde contouren.

CNC Draaibank Draaien Bewerking

CNC bewerkingsdraaibank onderdelen zijn cilindrisch en zeer nauwkeurig. Onconventionele CNC draaibanken met live tooling kunnen frezen en boren in één enkele opstelling uitvoeren voor lagere cyclustijden. In de luchtvaart- en auto-industrie hebben titanium en gehard staal rigide instellingen en snijparameters nodig. Toleranties binnen ±0,001 inch en oppervlaktekwaliteit tot Ra 0,4 µm zijn standaard. Toch moeten de snijcondities voortdurend bewaakt en aangepast worden.

5-assige CNC-bewerking Verspanende diensten

5-assig CNC bewerken biedt flexibiliteit en precisie voor onderdelen met ondersnijdingen en ingewikkelde geometrieën. Machines met dynamische opspanoffset en centrumpuntbesturing van het gereedschap kunnen toleranties van ±0,003 mm over alle assen handhaven. Toepassingen zijn onder andere onderdelen voor de ruimtevaart, medische implantaten en hoogwaardige auto-onderdelen. Gereedschapspadstrategieën en CAM-software optimaliseren de materiaalafname en cyclustijd voor een hoge productiviteit en kwaliteit bij de productie van grote volumes.

CNC-bewerkingscentra en bedieningspanelen

Bewerkingscentrum CNC frezen is essentieel voor de hedendaagse productie. Het beschikt over bedieningspanelen die het wijzigen van bewerkingsparameters in real-time versnellen. Hoogwaardige modellen zijn voorzien van adaptieve besturing, botsingvermijding en automatische gereedschapswisselaars. Bedieningspanelen voor 5-assig CNC frezen met intuïtieve en aanpasbare instellingen stellen operators in staat om processen nauwkeurig af te stellen. Connectiviteitsopties voor bewaking op afstand en IoT-systemen bieden mogelijkheden voor gegevensanalyse en voorspellend onderhoud.

Hout CNC-Dienst Machinale bewerking

5-assig CNC verspanen van hout vereist deskundige gereedschappen en technieken om de variabiliteit en korrelstructuur van het materiaal aan te pakken. Hogesnelheidsfrezen met spindelsnelheden van 12.000-40.000 tpm kunnen helpen om gladde sneden en lastige ontwerpen te maken. MDF, multiplex en hardhout vereisen verschillende gereedschapsgeometrieën en snijparameters. Stofafzuigsystemen zorgen voor een schone werkomgeving. Toepassingen variëren van op maat gemaakte meubels en kasten tot houtsnijwerk en architecturale elementen.

Bewerking draaien buisdeel CNC frezen POM onderdelen

Verspanen en draaien POM (Delrin) buisonderdelen optimaliseren snijparameters om materiaalvervorming tegen te gaan en nauwe toleranties te bereiken. CNC-draaibanken en freesmachines met precisiekoppen en -opspanningen zorgen voor een stabiele bewerking. Daarnaast omvatten de toepassingen bussen, afstandsstukken en onderdelen in auto's en industriële apparatuur met consistente prestaties.

POM Nylon ABS Delen Aangepaste Precisie CNC Machinale bewerking

Voor precisiebewerking op maat van POM, Nylon en ABS onderdelen zijn radicale CNC-apparatuur en gereedschappen nodig. Dergelijke materialen worden gebruikt in tandwielen, behuizingen en mechanische onderdelen. Vergeet niet dat nabewerkingsprocessen, zoals gloeien en oppervlakteafwerking, de betrouwbaarheid van onderdelen kunnen vergroten.

CNC Bewerkend Deel Aangepaste MC Nylon Geprofileerde Delen

Aangepaste bewerking van MC Nylon geprofileerde onderdelen bevat hoge precisie CNC freesservice en draaiprocessen. De slijtvastheid en mechanische eigenschappen van MC Nylon zijn geschikt voor tandwielen, lagers en rollen. Frezen met hoge voeding en precisieboren zorgen voor een consistente kwaliteit. Bovendien helpen maatinspectie en materiaaltesten om aan de industrienormen te voldoen.

Bent u op zoek naar de beste 5-assige CNC machinale bewerkingsdiensten? Neem dan contact op met MXY Bewerking omdat wij tot de top leveranciers van CNC freesonderdelen behoren. Niet alleen dat, maar we leveren ook eersteklas CNC-draaibankonderdelen en CNC-bewerkingsonderdelen voor aluminiumprofielen, samen met CNC-draaiaccessoires. Dus waar wacht u nog op?

bieden ook eersteklas CNC-draaibankonderdelen en CNC-bewerkingsonderdelen voor aluminiumprofielen, samen met CNC-draaiaccessoires. Dus waar wacht u nog op?