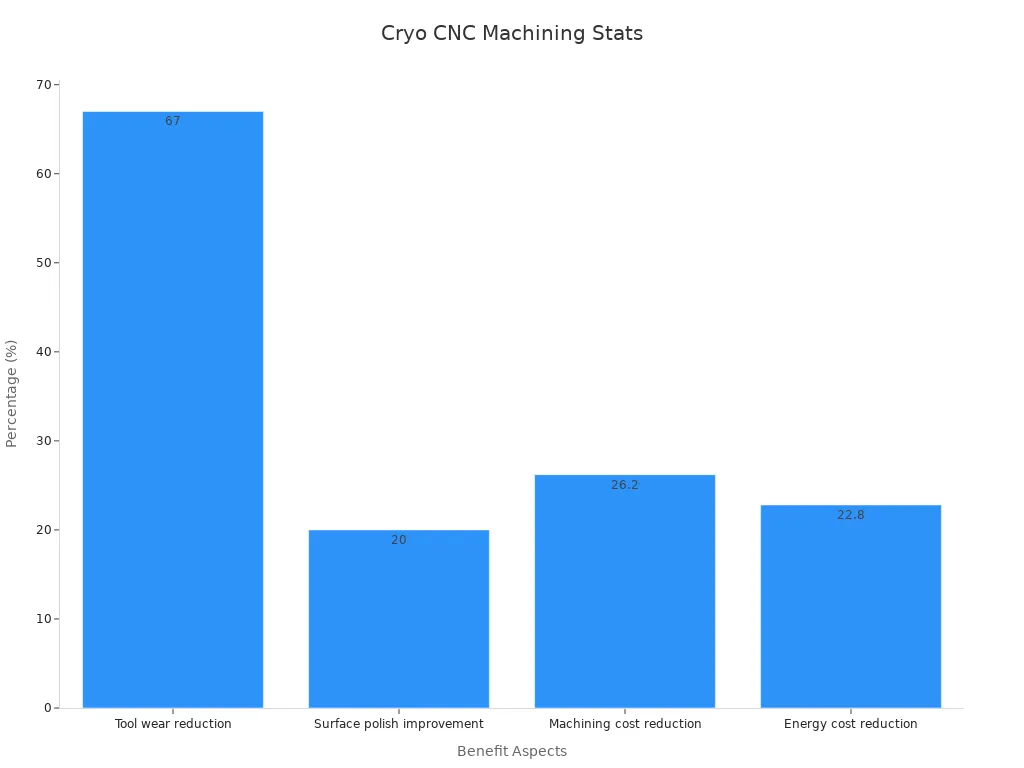

Cryogenic CNC Machining uses liquid nitrogen to cool things instead of oil-based fluids. This way, the cutting area gets cold very fast and tools stay sharp longer. Studies show tool wear goes down by 67%. Machining costs also drop by 26.2%.

Researchers found that liquid nitrogen cooling makes tools last longer. It also gives smoother surfaces and uses less energy. MXY gives solutions that help cut hard materials faster and better.

Hal-hal Penting yang Dapat Dipetik

- Cryogenic CNC Machining uses liquid nitrogen to cool tools fast. This helps tools last longer and makes surfaces smoother.

- This method lowers heat and friction. It lets factories cut metal faster and work more quickly.

- Cryogenic cooling can cut tool wear by up to 70%. This saves money on new tools and makes better parts.

- The process is better for the environment. It does not use oil coolants and uses less energy and makes less waste.

- Setting up cryogenic systems costs more money. You need special equipment and training to use them safely and well.

- Not all materials act the same way. Testing is needed to find the best settings for each metal.

- Operators must keep learning to use cryogenic liquids safely. They also need to know how to use advanced machine controls.

- Many industries use cryogenic machining. Aerospace, automotive, and medical companies use it for strong, precise parts.

How It Works

Liquid Nitrogen Cooling

Cryogenic CNC Machining uses liquid nitrogen (LN2) instead of oil-based coolants. LN2 cools the cutting area very fast and keeps it cold. This method takes the place of regular fluids and helps control heat. Researchers found that LN2 cooling can cut tool wear and cutting forces by half when working with tough alloys like Ti-6Al-4V. LN2 also makes less friction between the tool and the workpiece. This means tools last longer and surfaces look smoother.

Internal Tool Channels

Many new machines send LN2 right to the cutting edge through channels inside the tool. This design cools the hottest spot in the process. By putting LN2 where it is needed, the system removes heat better. MXY solutions use this idea to help people cut hard materials faster and with less tool damage.

Tip: Internal tool channels give very exact cooling. This is very important when working with advanced alloys or hardened steels.

Heat Absorption

LN2 takes in heat from the cutting zone by turning from a liquid into a gas. This change pulls energy away from the tool and workpiece. The cooling power depends on a few things:

- How fast LN2 flows

- How far the nozzle is from the cutting area

- The amount of liquid compared to gas in the nitrogen

A higher liquid amount cools better and helps stop overheating. Studies show LN2 can lower cutting temperatures by 16% to 37%, depending on the material. This drop in heat helps stop parts from changing shape and keeps the tool sharp.

Cryogenic CNC Machining Process

The steps for Cryogenic CNC Machining are:

- The machine sends LN2 through channels or nozzles to the cutting zone.

- LN2 cools the tool and workpiece, lowering heat and friction.

- The system controls LN2 flow to keep the temperature steady and stop thermal shock.

- The operator watches the process to make sure it is safe and works well.

Tests show this process can make tools last 40% to 200% longer than normal ways, especially at high speeds. LN2 cooling also makes surfaces smoother and sizes more exact. Researchers have seen lower cutting forces, better chip shapes, and less power used during cryogenic machining. But using LN2 on the workpiece for too long can sometimes make it harder, so most good results come from cooling the tool.

MXY has advanced systems that send LN2 automatically and watch important settings. These solutions help users get the same good results and make tools last longer, even with hard materials.

Catatan: Good LN2 flow and the right nozzle spot are very important for the best results in Cryogenic CNC Machining.

Manfaat

Faster Processing

Cryogenic CNC Machining lets machines cut metal much faster. The process uses liquid nitrogen at -321°F to cool the cutting edge quickly. This fast cooling lets workers use higher speeds and feeds. Machines can take away more metal in less time. Companies like 5ME and Okuma America have shown that cryogenic machining boosts productivity. Operators do not need to stop for coolant changes or cleaning. This keeps the process running smoothly. Higher speeds and less stopping mean more parts get finished each day.

Tip: Faster processing helps factories finish orders on time and handle big jobs.

Tool Life Extension

Cryogenic CNC Machining helps tools last much longer. The cold from liquid nitrogen lowers heat and friction at the cutting edge. Less heat means the tool does not wear out as fast. Many studies show big gains in tool life. The table below shows results from different researchers:

| Study (Authors) | Bahan | Improvement in Tool Life or Wear Reduction |

|---|---|---|

| Hong et al. (2001) | Ti-6Al-4V | Tool life extended by 5 times compared to conventional machining |

| Wang and Rajurkar | Tantalum | Tool wear reduced by 70% under cryogenic machining |

| Venugopal et al. | Ti-6Al-4V | Reduced flank and crater wear at 70 m/min cutting speed |

| Sivaiah and Chakradhar | 17-4 PH Stainless Steel | Cryogenic turning showed superior tool wear performance |

| Kumar and Choudhury | Baja tahan karat | Reduced tool wear and cutting forces under cryogenic conditions |

Lockheed Martin saw a 52% faster machining rate on a titanium part using cryogenic machining. In another case, cutting speeds for cobalt-chrome went from 100-125 sfm to 550-700 sfm. These results show that tools stay sharp longer and can handle harder jobs. The process also works well with brittle tool materials like alumina ceramics. By keeping tools cooler, cryogenic machining stops damage and saves money on new tools.

Kualitas Permukaan

Cryogenic CNC Machining gives parts a smoother finish. The cold keeps the cutting area cool, which helps control the shape and size of the part. Tests show that cryogenic methods lower surface roughness more than dry processes. The table below compares results:

| Quality Benchmark/Test Parameter | Dry Process Result | Cryogenic Process Result | Significance/Impact |

|---|---|---|---|

| Surface Roughness Reduction (Ra) | Up to 74% reduction | Up to 77% reduction | Better surface finish, important for aerospace parts |

| Surface Roughness Reduction (Rz) | Up to 71% reduction | Up to 76% reduction | Improved surface integrity |

| Temperature During Machining | Approx. 60 °C | Maintained ≤ 20 °C | Lower temperature reduces thermal damage |

| Thermal Expansion (Dimensional Change) | 0.058 mm | 0.020 mm | Maintains tight tolerances (±0.02 mm) |

| Tool Wear and Machining Efficiency | Higher tool wear | Reduced tool wear, better efficiency | Balances tool wear and surface quality |

Cryogenic machining keeps the temperature low, so parts do not expand or change shape. This control helps meet strict size limits, especially in aerospace work. Lower temperatures also mean less stress on the part, so the surface stays smooth and strong. Operators see less tool wear and better efficiency, making this process a smart choice for high-quality parts.

Dampak Lingkungan

Cryogenic machining is better for the environment in many ways. Factories use liquid nitrogen or carbon dioxide to cool things. They do not need oil-based coolants anymore. Oil-based coolants can hurt the ozone layer. They also make waste that can pollute water and soil. By not using these fluids, companies keep people and nature safer.

- Cryogenic setups do not make any lubricant waste. Traditional machining uses cutting fluids that turn into dangerous waste.

- The process makes fewer toxic emissions. No oil-based coolants means no bad fumes or spills.

- Tool life gets better by 15% to over 300% for many steels. Longer tool life means fewer tools end up in landfills.

- Cutting forces go down by about 18% to 43%. Lower forces mean machines use less energy.

- The temperature in the cutting area drops by 30% to over 50%. This stops thermal damage and keeps the air cleaner.

- Material removal rates rise by about 23%. Workers finish jobs faster and save more energy.

- Power use goes down by about 320 watts during machining. Using less power means a smaller carbon footprint.

🌱 Catatan: Cryogenic machining is a cleaner and greener choice. It helps factories follow strict environmental rules and keeps workers safer.

Studies show these changes make cryogenic machining better for the planet. Factories that use this method help lower pollution and save resources.

Kekurangan

Biaya

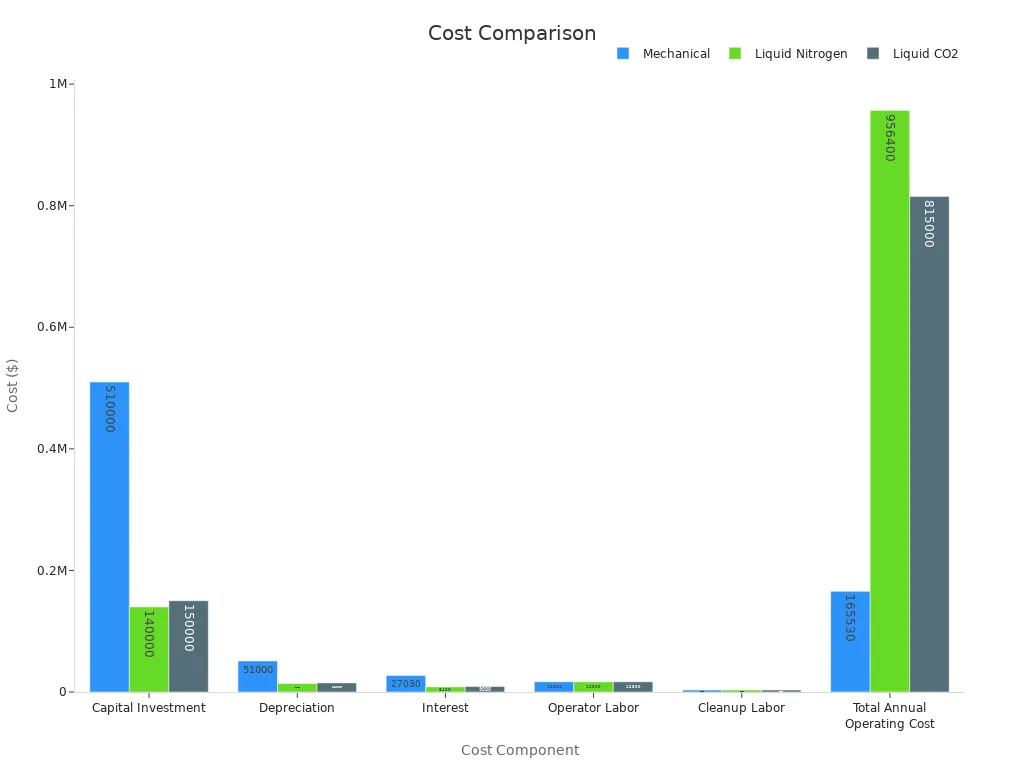

Cryogenic machining costs more to start than regular machining. Companies must buy special equipment for this process. They need things like vacuum-jacketed feed lines and through-tool cooling systems. These parts help bring liquid nitrogen to the cutting edge. The machines also need advanced controls to manage nitrogen flow. This makes the first investment much higher than with oil-based coolants.

The table below shows how much more cryogenic systems can cost each year:

| Cost Component | Mechanical System (Annual) | Liquid Nitrogen System (Annual) | Liquid CO2 System (Annual) |

|---|---|---|---|

| Capital Investment (Installed) | $510,000 | $140,000 | $150,000 |

| Depreciation (10%) | $51,000 | $14,000 | $15,000 |

| Interest (12%) | $27,030 | $8,400 | $9,000 |

| Pemeliharaan | $20,400 | $14,000 | $15,000 |

| Power Cost | $51,000 | N/A | N/A |

| Operator Labor | $16,800 | $16,800 | $16,800 |

| Cleanup Labor | $3,200 | $3,200 | $3,200 |

| Freezants Cost | N/A | $900,000 | $756,000 |

| Total Annual Operating Cost | $165,530 | $956,400 | $815,000 |

| Unit Operating Cost per lb. | $1.12 | $7.97 | $6.79 |

The table and chart show cryogenic systems cost much more to run. Most of the extra cost comes from buying liquid nitrogen or carbon dioxide. These high prices make it hard for small shops to use cryogenic machining. Even though tools last longer and less oil is used, the coolant cost is still a big problem.

💡 Catatan: Cryogenic systems save money on coolant disposal and tool replacement, but the high price of liquid nitrogen often cancels out these savings.

System Complexity

Cryogenic machining setups are harder to use than regular ones. They need special parts to handle very cold liquids. These include insulated pipes, advanced valves, and nozzles for the coolant. The machines also use sensors and controls to keep the temperature steady.

A study listed some ways these systems are more complex:

| Complexity Metric | Description / Role | Effect on Machining Setup Integration and Performance |

|---|---|---|

| Supply Temperature | Adjustable from ambient down to -40 °C using cryostat and heat exchanger | Influences thermal gradient, cooling performance, and viscosity of metalworking fluid |

| Volume Flow | Measured via flow meter; varied during experiments | Affects cooling rate and thermal load; higher flow improves cooling but interacts with outlet velocity |

| Mass Flow | Calculated from volume flow and fluid density | Higher mass flow enhances heat removal; critical for thermal load reduction |

| Outlet Velocity | Calculated based on nozzle diameter and volume flow | Higher velocity improves convective heat transfer and wetting of cutting zone |

| Supply Pressure | Derived from fluid density and outlet velocity | Higher pressure promotes better coolant application and lubrication at cutting zone |

| Nozzle Outlet Diameter | Two sizes tested (1 mm and 2 mm) affecting outlet velocity and pressure | Smaller diameter yields higher velocity and pressure, improving cooling and lubrication |

| Thermal Insulation | Applied to components to prevent thermal bridges | Necessary for maintaining low coolant temperatures and system efficiency |

| Valve Coupling with NC Control | 3/2-way valve integrated with CNC control for precise coolant application timing | Adds complexity in system integration but enables optimized cooling strategies |

| High-Speed Imaging | Used to analyze wetting behavior and coolant interaction with cutting zone | Provides insight into lubrication and cooling effects, supporting optimization |

Operators must learn new controls and keep the system safe. The extra parts and controls make repairs and maintenance harder. If something breaks, it can take longer to fix than a regular coolant system.

⚠️ Tip: Shops should plan for extra training and possible downtime when switching to cryogenic systems.

Material Limits

Not all materials work well with cryogenic machining. Some metals, like aluminum alloys with nano-sized particles, have mixed results. For example, Al 8011 with nano-sized SiC particles gets harder and finer grains after cryogenic machining. But the surface can get rougher than with other cooling methods. Tool wear also changes with cutting speed and coolant type. Sometimes, canola oil reduces tool wear better than cryogenic cooling at certain speeds.

Aerospace materials like Ti-6Al-4V have also been tested. Studies found cryogenic cooling can double tool life and improve material removal. Still, there are times when tool wear increases quickly, so the process needs careful control. Fast heating and cooling can change the metal’s structure, making it harder or more brittle.

📌 Catatan: Each material reacts differently to cryogenic cooling. Shops must test their materials to find the best settings and avoid unwanted results.

Training Needs

Operators need special training to use cryogenic machining systems. These systems use very cold liquids and advanced controls. Workers must learn new skills to use them safely.

Many companies want operators to know several things. They look for people who understand how instruments and controls work. Operators should know about gas processes. They also need to know some basics about electricity and electronics. It is important to know about hardware because these machines have many moving parts and sensors.

🛠️ Tip: Operators should practice reading and understanding different drawings. These include instrument, piping, electrical, and electronic diagrams. This helps them fix problems faster.

Most jobs make operators finish training before working alone. Training teaches how to use the machines and handle liquid nitrogen. It also covers safety rules. Workers must show they can make good choices and work by themselves. Many companies want a high school diploma or GED. Some like people with a technical degree, college classes, or military training. Vocational apprenticeships also help workers get ready for these jobs.

Operators need strong math and computer skills. They use computers to control the machines and check data. Math helps them measure parts and set up the process. Training often gives practice with these tools.

Work hours can include nights, weekends, and holidays. Operators must be ready to work at different times. Being dependable and able to adapt is important. Some companies call the night shift the “Owl shift.” Workers must finish all training before working these shifts.

📚 Catatan: Operators must keep learning new things. They need to know the latest safety rules and machine updates.

Training does not end after the first lessons. Operators must keep learning as machines and processes change. They follow strict safety and work rules every day. Companies may give more classes or hands-on practice to help workers stay sharp.

A normal training program might include:

- Safety steps for handling cryogenic liquids

- How to run and fix the machine

- How to read technical drawings and diagrams

- Computer and math skills for process control

- What to do in emergencies

- Ongoing learning and skill updates

Good training keeps workers safe and helps machines work well. Companies that train workers have fewer accidents and better results.

Keamanan

Operator Protocols

Operators have special risks when using cryogenic gases like nitrogen, helium, argon, and carbon dioxide. These gases can lower oxygen in the air. If there is not enough oxygen, people can suffocate. The cold from these liquids can freeze skin and cause frostbite. When the liquid turns into gas, it grows fast and can fill a room. This can push out the oxygen without warning. Operators must follow strict safety rules to stay safe.

1. Always read safety rules before starting or after changes. 2. Wear PPE like safety glasses, face shields, insulated gloves, long sleeves, long pants, and strong shoes. 3. Only use containers and pipes made for very cold liquids. 4. Move cryogenic fluids slowly and keep them below your chest to stop splashing. 5. Work where air moves well or use oxygen monitors to check the air. 6. Make sure all systems have pressure relief valves. 7. Never close liquid nitrogen containers tightly. 8. Know what to do if there is a spill or someone gets hurt, including first aid for skin or eyes.

Operators need regular training. They must learn how to use gases, handle equipment, and follow emergency plans. Companies want operators to pass safety classes and keep learning new skills.

⚠️ Tip: Always look for leaks and wear the right gear before working with cryogenic fluids.

Keamanan Peralatan

Machines used for cryogenic work must pass many tests to show they are safe. Seals and parts are tested in the cold to see if they stay strong and flexible. Chemical tests check if seals can stand up to harsh chemicals. Pressure tests make sure parts can handle changes in pressure.

- Impact tests check if materials can take hard hits without breaking.

- Creep tests see if materials change shape when pushed for a long time.

- Non-destructive testing uses special tools to find hidden cracks or problems without breaking the part.

- Cryogenic tests make sure materials work well in very cold places.

All machines need pressure relief valves and alarms. Trained workers must check and fix equipment often. Companies follow rules from groups like OSHA and ISO to make sure machines are safe.

Emergency Response

If something goes wrong, acting fast can save lives. Operators must know what to do if there is a spill, leak, or someone is exposed to cryogenic fluids. The plan should include:

- Leaving the area if oxygen drops or there is a leak.

- Giving first aid for frostbite or eye contact. Warm the area slowly and get medical help.

- Stopping machines with emergency buttons.

- Calling emergency services if needed.

Companies should practice drills so everyone knows what to do. Emergency kits with first aid and oxygen monitors should be easy to find. Signs and alarms help warn workers about danger.

🚨 Catatan: Fast action and good training help stop injuries and keep everyone safe.

Implementation

Setup Steps

To set up a cryogenic CNC machining system, shops follow several steps. First, they pick a CNC machine that works with the system. The workspace must be ready and safe. The team puts in a liquid nitrogen supply, usually a 200-liter gas cylinder with a pressure cap valve. They attach vacuum-insulated pipes to the machine. Flexible hoses help bring the coolant to the tool holder. Many tool holders have nozzles built in for the coolant. For example, the Kennametal DCLNL20X12 JETI holder has two nozzles that point at the cutting insert.

Operators must use safety gear like gloves, face shields, aprons, and special shoes. The shop needs good airflow and oxygen monitors to keep everyone safe. Training teaches how to store and move liquid nitrogen safely. The team tests the system by running coolant through the nozzles and checking for leaks. They also set up alarms and emergency shutdown steps.

🛠️ Tip: Shops should plan regular checkups and make sure all workers get trained before starting work.

Machine Compatibility

Cryogenic CNC machining systems fit many kinds of machines. Tests show that vertical machining centers, turning centers, and 5-axis machines can all use cryogenic cooling. For example, the MAG cryogenic system works on NBV 700 5X vertical centers, VDM 1000 turning centers, and HERMLE 5-axis machines. These systems also work with robotic arms and machines without hydraulics.

Companies like DMG MORI, OPS-INGERSOLL, and HERMLE have tried their machines with cryogenic setups. Results show tools last twice as long, feed rates go up, and productivity can rise by 30%. Shops use these systems to cut aerospace titanium, Inconel, hardened shafts, and wind turbine parts. Because so many machines and materials work, cryogenic machining is a flexible choice.

| Jenis Mesin | Example Model | Application Area |

|---|---|---|

| Vertical Machining Center | NBV 700 5X | Aerospace, Medical |

| Turning Center | VDM 1000 | Automotive, Energy |

| 5-Axis Machining Center | HERMLE C42U | Tooling, Aerospace |

| Turn/Mill Center | VDF 450 TM | General Engineering |

Transition and Reversion

Shops that switch from regular to cryogenic CNC machining often start with a test project. Research labs like the University of Kentucky found that cryogenic cooling helps tools last longer and gives smoother surfaces. For example, Yang and his team made hip implants stronger using cryogenic methods. Kumar and Jawahir found it easier to machine hybrid composites.

The change includes adding cryogenic parts to machines and training workers. Shops may need to change cutting settings and try different nozzle spots. If they want to go back, they can remove the cryogenic parts and put back the old coolant lines.

🔄 Catatan: MXY helps shops add or remove cryogenic systems and trains workers to make the change easy.

Aplikasi

Suitable Materials

Cryogenic CNC Machining works best on tough, heat-resistant metals. Many shops use it for hardened steels like AISI 4340 and alloys such as titanium and Inconel. These metals are hard to cut with regular methods. They get hot fast and wear out tools quickly. Cryogenic cooling keeps the cutting area cold. This helps control heat and slows down tool wear.

Powdered metals also do well with this process. The cold helps keep their structure strong while cutting. Tool steels need to be hard and tough. After cryogenic treatment, they resist wear better. This method also makes many alloys stronger. It helps them last longer in hard jobs.

Tip: Shops should test each material before full production. Some metals act differently when very cold.

Industry Use Cases

Many industries use Cryogenic CNC Machining for strong, precise parts. This process is good for companies that need tough materials and exact sizes. Some main industries are:

- Otomotif

- Dirgantara

- Space

- Pertahanan

- Mesin Industri

- Pembangkit Listrik

- Energi

- Semikonduktor

- Medis

- Tool & Die

These industries need parts that handle stress and wear. Cryogenic treatment makes metals tougher and more durable. For example, aerospace companies use it to make titanium airplane parts. Medical device makers use it to shape stainless steel for implants. Power plants use it to make turbine blades from special alloys.

Cryogenic treatment puts metals in very cold temperatures, from -190 °C to -230 °C. This step makes metals harder and helps them last longer. Studies show steels like AISI 4340 get stronger after this treatment. Many companies use cryogenic machining to make better, longer-lasting parts.

Studi Kasus

Real-world results show cryogenic machining works well. In one study, engineers used cryogenic cooling on A390 alloy with high-speed steel tools. Tool life got over 1000% better. The process made chip handling easier and raised productivity. These results happened in turning, milling, grinding, and drilling.

Aerospace factories saw smoother surfaces and tighter sizes on titanium and Inconel parts. Medical companies had fewer tool changes and better part quality for surgical tools. MXY has helped many shops upgrade their systems. Their solutions let users cut hard materials faster and with less tool damage.

🏆 Catatan: Many industries now use cryogenic machining for parts that must be strong, exact, and last a long time.

Cryogenic CNC Machining cools the cutting area with liquid nitrogen or CO2. This helps tools last longer and makes surfaces smoother, especially on hard metals. Many tests show it works better than oil-based coolants. People using this method make less waste and have safer work areas. But it costs more and the setup is harder. Not every material reacts the same way. Shops can ask MXY for help or check technical guides to learn more.

- The cutting area gets colder, so tools last longer.

- Surfaces can be very smooth, even down to 0.712.

- Sometimes, cutting forces get higher.

- Scientists need to study milling and drilling more.

PERTANYAAN YANG SERING DIAJUKAN

What is the main advantage of cryogenic CNC machining?

Cryogenic CNC machining keeps tools much cooler. This makes tools last longer and gives smoother parts. Factories can cut hard metals faster and spend less on new tools.

Is liquid nitrogen safe to use in machining?

Liquid nitrogen is safe if workers follow all safety steps. Operators must wear gloves, face shields, and special clothes. Good training and the right gear help stop accidents.

Can any CNC machine use cryogenic cooling?

Not all CNC machines can use cryogenic cooling. Some machines need extra parts or upgrades first. Shops should ask the machine maker or a cryogenic expert before starting.

Which materials benefit most from cryogenic machining?

Hard metals like titanium, Inconel, and hardened steels get the most help. These metals get hot fast and wear out tools quickly. Cryogenic cooling keeps them cooler and helps cutting.

Does cryogenic machining cost more than traditional methods?

Cryogenic machining costs more at the start. Shops must buy special gear and liquid nitrogen. Over time, longer tool life and less waste can help balance the higher cost.

How does cryogenic machining help the environment?

Cryogenic machining does not use oil-based coolants. This means less chemical waste and fewer bad fumes. Factories using this method help keep air, water, and soil cleaner.

What training do operators need for cryogenic CNC machining?

Operators need special training for this job. They learn to handle liquid nitrogen, use safety gear, and run the machines. Regular practice and safety classes help everyone stay ready.

Can shops switch back to regular coolant systems?

Shops can switch back if they need to. They take out the cryogenic parts and put back the old coolant lines. Some shops try both ways to see which works best.